OCSiAl: World’s Largest Graphene Nanotube Manufacturing Hub in Luxembourg

- A flagship graphene nanotube facility in Luxembourg, a $300 million deep-tech investment, is set to put Europe at the forefront of advanced materials innovation.

- The Luxembourg facility will bring more than 300 new jobs and serve as a scalable energy-efficient manufacturing center.

- The launch follows a recent investment round from Luxembourg investors and the signing of a long-term land lease with the State of Luxembourg.

OCSiAl, a Luxembourg-based deep-tech company and the global leader in graphene nanotube technologies, has announced the signing of a land lease, launching the development of its flagship graphene nanotube production center in Differdange, Luxembourg, that will become the world’s largest graphene nanotube production facility.

This official announcement is a culmination of a years-long effort by the company and the Luxembourg Government, including most recently an investment round raised from a “club” of Luxembourg-based investors and the signing with the State of Luxembourg of a long-term land lease for a 3.63-hectare site in Differdange.

“The launch of this future production center in Differdange perfectly illustrates our ambition to position Luxembourg as a key player in industrial innovation in Europe. This major investment in graphene nanotubes demonstrates investors’ confidence in our ecosystem and highlights the potential of our business parks to host high-tech industrial projects. We are proud to support OCSiAl in this strategic step, which will contribute to the creation of skilled jobs, the reputation of Luxembourg in deep-tech, and the transition to a more sustainable and competitive industry,” said Lex Delles, Minister of the Economy, SME, Energy & Tourism.

“OCSiAl’s investment highlights Luxembourg’s role as a platform for long-term innovation and smart industrial development,” added Gilles Roth, Minister of Finance. “This project reflects the value of combining private sector vision with public infrastructure support.”

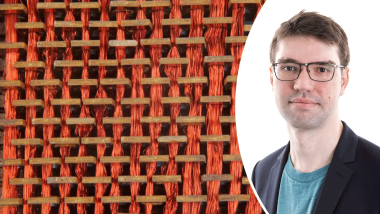

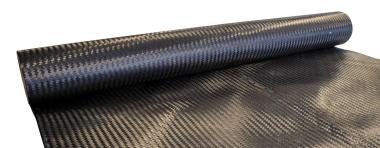

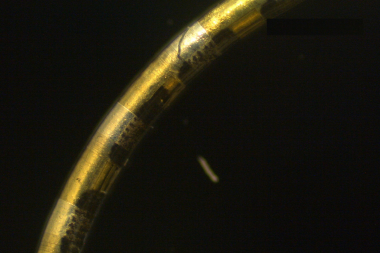

Founded in Luxembourg in 2010, OCSiAl has become the world’s largest producer of graphene nanotubes, a next-generation material that offers exceptional performance to a multitude of products used in everyday life. OCSiAl’s nanotubes, currently produced only in Serbia, where the company is increasing production capacity fourfold, are already used in more than 10% of smartphones sold today and in over one million electric vehicles worldwide.

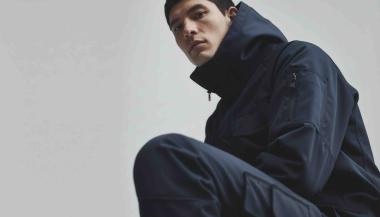

“Graphene nanotubes can improve over half of the materials we use every day, from safer batteries to longer-lasting tires and ultralight protective equipment,” said Alain Kinsch, a member of the OCSiAl Board of Directors. “We thank the Luxembourg Government for enabling this project through the land lease and for fostering an environment where innovation and industrial ambition can thrive.”

OCSiAl