Indorama Ventures strengthens its management council with new role rotations

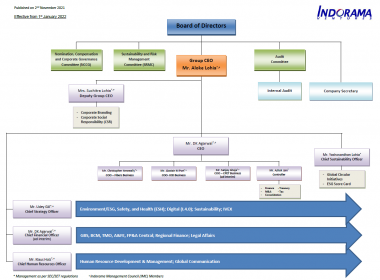

Indorama Ventures Public Company Limited announced it has strengthened its Indorama Management Council (IMC) – the company’s highest operational management committee – by rotating experienced executives and adding the COOs of the Fibers and Integrated Oxides & Derivatives (IOD) segments.

The elevation of Mr Christopher Kenneally, COO of Fibers, and Mr Alastair Port, COO of IOD, to the IMC – will enable more agile decision making as they build their high-growth segments into self-sustaining organizations that maximize value for IVL stakeholders. The appointments are effective immediately.

In a rotation of roles, Mr Sanjay Ahuja, the current CFO of IVL, will switch to Interim COO of Combined PET (CPET) for a period of 2 years, effective January 2022, as part of a rotation of senior expertise across the IMC. He will report to Mr D K Agarwal as CEO, who will take on additional broader responsibilities as CFO. The CPET role rotation will enable new dynamism in this largest segment of IVL and establish a self-sustaining organization for the permanent successor that IMC selects over this period. Mr Agarwal will be supported by Mr Ashok Jain in an enhanced role as Controller, covering Banking & Finance, Global Consolidation, Taxation and M&A.

Further, Mr Klaus Holz will join the IMC as Chief Human Resources Officer, effective 1 January 2022. He replaces Mr Roberto Bettini who will retire at the end of 2021.

Indorama Ventures Limited Indorama Ventures Public Company Limited Fibers chemicals petrochemicals

Indorama Ventures Public Company Limited