Bangladesh Denim Expo re-opens its doors with theme “Beyond Business”

- Renowned global denim event goes live again after two years

- Bangladesh Denim Expo brings together the global denim supply chain

- The show has a sustainability focus, and a central theme of ‘Beyond Business’

- Bangladesh is the 2nd largest denim exporter to the EU and the third largest to the United States

After a two-year break, Bangladesh Denim Expo will once again open its doors in the international Convention City, Bashundhara (ICCB) in Dhaka on May 10th & 11th 2022. The event is now firmly established as one of the world’s leading denim trade shows, and its live return is a huge boost to the global denim manufacturing sector.

“Beyond Business” is the theme of the 12th edition of the show. Bangladesh Denim Expo addresses the new opportunities for successful & sustainable business, in a world that now demands that industry leaders to go “Beyond Business.”

79 Exhibitors are set to attend the event, consisting of both local and international participants.

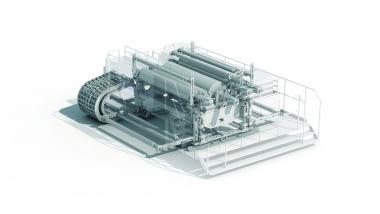

In this edition exhibitors will display fabrics, garments, threads, machinery, finishing equipment and accessories, positioning the show as a true representation of Bangladesh’s denim industry - the second largest denim exporter to the EU and third largest to the United States.

Through a series of product displays, seminar sessions & panel discussions, the Expo will encourage robust debate and interaction among exhibitors and visitors.

8 seminar sessions conducted by exhibitors at the two days event, and two panel discussions, reflecting the overriding sustainability theme of this edition of the Expo.

Industry experts will gather to discuss how the denim industry can improve, not only from a business perspective, but also considering social and environmental impacts and goals.

Denim Expert Ltd