Intertextile Shanghai Home Textiles attracted more trade buyers this year resulting in strong business outcomes

Overseas exhibitors found the fair an effective platform to open up the Asian market

Buyers benefited from wide range of quality exhibitors

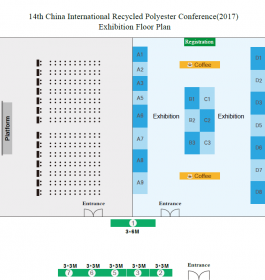

The 23rd edition of Intertextile Shanghai Home Textiles is over, with both exhibitors and buyers satisfied with the business outcomes resulting from the fair’s four days. The largest home textiles trading event in Asia was held from 23 – 26 August, attracting 1,106 exhibitors from 30 countries and regions. Given the strengthening market conditions in China the fair maintained its popularity, with the number of trade buyers increasing to 38,964 from 99 countries and regions (2016: 37,779 from 98 countries and regions). The show also attracted more international buyers this edition, with a 16% increase in those coming from abroad. “Intertextile Shanghai Home Textiles has once again proven its leading position in Asia as a business and order platform for the industry. There was a noticeable positivity from both exhibitors and buyers this edition regarding the current and future situation of the domestic market, so we are optimistic about the industry for the next year,” Ms Wendy Wen, Senior General Manager of Messe Frankfurt (HK) Ltd said.

Overseas exhibitors found the fair an effective platform to open up the Asian market

As the leading event of its kind in the region, the fair successfully attracts a number of Chinese and Asian buyers every year, ensuring suppliers can develop their business further in the region. This year, seven country and region pavilions including Belgium, India, Korea, Morocco, Pakistan, Taiwan and Turkey were formed, with exhibitors from all of satisfied they could meet their target buyers.

While being in the minority at the fair, European brands still managed to catch the attention of visitors due to strong interest in their products from Asia. The Italian upholstery supplier Enzo Degli Angiuoni Spa was satisfied with the number of Asian buyers, particularly Chinese, that they met at the fair. Mr Stefano Laurenzano, Export Area Manager expressed: “A lot of visitors that saw us here last year have come back again and are serious about cooperating with us. Here you can get a lot of new contacts and discover the Asian market. We’ve had mainly Chinese buyers, but have had more Asian buyers from South Korea, India, Malaysia and elsewhere to visit us this year. We are seeing more business here in recent years.”

Being a newcomer to the fair, Iceland Duvet ehf felt the potential in China. “We’ve had enough buyers including retailers and manufacturers visiting our booth to make our participation worthwhile. The interest from the buyers has been genuine. Being a European brand helps more than at fairs in Europe as we can stand out more here,” Mr Ragnar Ludvik Runarsson, representative said.

Indian exhibitor, Paramount Textile Mills Ltd has been joining the fair for three years. “Apart from meeting our existing customers, we’ve had enquiries from potential new customers from China as well as overseas including the US and South America,” Mr Ram. M., Director of Marketing & Finance said.

Also with three years’ participation, Mr Samir Tazi, General Manager of PIF Textile Emotions from Morocco affirmed the show’s effectiveness in meeting important buyers and decision makers. “It’s easier for us to meet them here compared with some smaller European fairs. Thanks to Intertextile Shanghai, we have also met the major players in China.” Talking about this year’s result, he continued: “We were very busy. We met with more people than any other fairs. There are a lot of new buyers and also returning buyers checking out our new products.”

Participating in the Korea Pavilion, Sangwon Textile Co Ltd found the fair helpful in attracting distributors and wholesalers from Southeast Asia. Mr Jeon Hyeon Tae, Sales Manager said: “We have found about five potential and quality distributors from Taiwan, India, Philippines and Singapore on the first day. We also got to meet a number of wholesalers who prefer to buy from us directly at the fair.” He added that Intertextile Shanghai is also an ideal platform to launch new products for their existing clients.

As the largest pavilion this year, the Turkey Pavilion was in the limelight of the show, with both new and veteran exhibitors finding it useful to exhibit in Intertextile Shanghai. Bezmez Ev Tekstil did not intend to receive any orders in their first show, but was surprised to obtain three in just one day. These concrete results reassured their likelihood of coming back next year. “We definitely see the potential for Turkish products here in China as Chinese companies prefer quality products nowadays,” Mr Ayhan Bezmez, representative, further commented. Mr Fahri Goksin, Vice President of Gokhan Tekstil agreed with Mr Bezmez that Chinese buyers are in favour of new things like imported goods and Western brands. His company has been in the Shanghai fair for six years and continued to get satisfactory results. “We’re looking for retailers, wholesalers and online buyers. We’ve had all of these visiting our booth already.”

Domestic exhibitors satisfied with the number of potential customers and orders received

Recently, there is strong signs suggesting that the home textiles market in China is recovering with both imports and exports rising gradually. The positive outcome that Chinese exhibitors achieved at the August’s fair have resonated with the market condition. It is no surprise to see a number of domestic booths packed with visitors throughout the days. SohoCUT is a case in point. To them, Intertextile Shanghai is the place for actual business. “Compared with other fairs we’ve been to, this is the exhibition where a huge number of international buyers gather. We met buyers from China, Mexico, Russia, the US, India and Southeast Asia. We even got large orders for the first two days.” Mr Wheatley Weng, Managing Director said.

The fabrics of Wujiang Linwang Weaving Mill is also sought after at the fair. Being a company that do both exports and domestic trade, they are happy to connect with local and overseas customers during the show. “We’ve collected around 100 leads on the first day, of which 70% are domestic and the remaining being international. The overseas visitors are from Italy, Poland, Germany, Denmark, Chile and Korea that our products precisely meet their requirement. We see high chances of cooperation after the fair.” Mr Kenny, Sales Manager said.

Given the prevailing smart home concept in China, Somfy China Co Ltd which specialised in advanced sun-protection system has become one of the highlights at the fair. Ms Nancy Nan, Chief Executive Officer mentioned: “The visitor flow has been really high that our booth is swarmed by buyers. Amongst those visitors, there is no lack of medium to high-end customers who placed orders immediately.”

Editors assembled to promote high-end products

To cater to the ascending standards of Chinese customers, Intertextile Shanghai once again brought editors together in hall 5.1 to maximise their exposure to their target buyers. As foreign brands with subsidiaries in China, JAB and Prestigious see the growing interest in their premium products in China. “We pay attention to the changing buying habits of Chinese consumers and, as such, have started promoting a series of products under a unified lifestyle trend. It’s obvious that we are gaining more awareness from buyers at the fair,” Mr William Lin, Vice President of JAB ANSTOETZ Interior (Shanghai) Co Ltd said. He also appreciated the specific display area for imported fabrics and the organisers’ attempt to attract more designers, which helped them meet more potential customers. Apart from getting onsite orders, Prestigious Textiles (Shanghai) Ltd also considers the show a promotion platform. “There is great demand for our products in China. Though we achieved similar sales compared with last year, through this fair our brand has been well introduced to the market,” Mr Lewis Liu, Sales Director expressed.

Originating from China, Euroart Co Ltd was another editor that successfully showcased their latest collection at the fair. “It is a good time to join the most influential home textiles exhibition in Asia as we have just launched new products in May. We are satisfied as some of our existing clients plus new visitors came to our booth,” Ms Guo Jianhua, Director Assistant said.

Industry players benefit from the expanded Digital Printing Zone

The demand for digital printing solutions has been growing in recent years, especially as the industry has put more emphasis on green production. As such, the Digital Printing Zone expanded in size this edition, incorporating a Seminar Area and more exhibitors.

As an Italian company, MS Printing Solutions Srl experienced the potential of the sector in China. “The fair has been busy, and we’ve had steady flow of buyers coming through. The potential in digital printing here is just beginning. The Chinese government is pushing companies to reduce their pollution, so it has a big advantage in this regard over traditional textile printing,” Mr Walter Oggioni, Regional Sales Manager stated, adding that the company has been growing very fast globally, especially in China, Turkey, India and Pakistan.

This potential holds for domestic machine manufacturers as well. Specialising in the production of digital printing machines, Guangzhou Xu Cheng Electronic Technology Co Ltd was at the fair to meet fabrics suppliers. Mr Jesse Luo, Overseas Manager explained: “Compared with exhibitions for textile machinery, Intertextile Shanghai attracts more fabrics suppliers, which are our target clients. It helps even more as we are located in this special zone. We’ve been talking to a lot customers, including overseas buyers who are also interested in our machines.”

A series of seminars also provided opportunities for the industry to share their insights on this emerging sector. As a speaker, Foshan Sanshui Yingjie Precision Machinery believed the session was mutually beneficial for them and the audience. “Attendees are from the whole sector including manufacturers and end users, so we can discuss different perspectives. It will facilitate our improvement,” Mr Peng Jichang, General Manager said. Mr Scott Bai, representative of Huntsman Textile Effects (China) Co Ltd also benefited from visiting the zone and the seminar. “Together with seminar, the Digital Printing Zone can professionally present the current situation for the industry. When suppliers and users come together, we can discover the way to enhance this technology.”

Buyers benefited from wide range of quality exhibitors

Intertextile Shanghai is the largest trading platform in Asia with the whole spectrum of home textiles and accessories on offer. Hence, visitors, be they Chinese or overseas, can access a wide range of quality suppliers that meet their sourcing needs. Australian buyer, Mr Glenn Whitchurch from Trabeth Textiles, was impressed with his sourcing journey. “The polyester quality of domestic exhibitors has been unbelievable. What’s more, we’ve found the Chinese suppliers to be very flexible in meeting our needs, they’re clearly keen to accommodate overseas buyers.” Mr Whitchurch also commented favourably on the product range at Intertextile Shanghai compared to European fairs.

One ongoing trend at the fair over recent years is the increasing quality of domestic suppliers, which attracts buyers to come back and source. Mezanin V SRL from Moldova is a long-term supporter of the show, and place orders every year. Its Vice Director, Mr Mihail Tornea remarked: “It is an important event for us to meet new suppliers from China. We are selective with the suppliers we work with, but the Chinese companies here meet our requirements. As a sourcing event, Intertextile Shanghai is the best place to be.”

The fair’s VIP buyer programme also assists buyers in meeting worldwide exhibitors at ease. Mr Bibo Lan is the co-founder of Loft Curtains in the US and he is excited to meet lots of potential suppliers here. “The arrangement for VIPs is satisfying and it helps a lot to have my target exhibitor information in advance. The largest benefit of our visit is that we met Libeco from Belgium, while we also confirmed to work with a blackout supplier at the fair,” he said.

Chinese buyers agreed that Intertextile Shanghai is the most effective sourcing platform in Asia. “Overseas suppliers like Turkey exhibitors are our main interest. So far, we have connected with four to five exhibitors in hall 4 and will place orders with them soon. In terms of exhibitor number and the product range, I feel that the fair has improved a lot. It is my favourite show with a lot of overseas products to discover,” Mr Huang Shenghua, General Manager of Ziranfeng Home Textile Co Ltd said.

Concurrent events inspired the industry

Apart from facilitating business between exhibitors and visitors, the fair also incorporated various design elements via a series of concurrent events. These included display area like Trend Area, International Fiber Art Exhibition and Home Furnishing Crossover Exhibition where participants could find innovative designs and ideas.

This was also the first time the Andrew Martin International Interior Design Summit and the fair took place concurrently. Experts from the interior design, architecture and art sectors were invited to share and discuss their views on the transformation of design in the new information era. Mr Kot Ge, founder of a domestic interior design studio, LSDCASA was delighted to join, and shared: “This show always attracts many top interior designers and it’s my pleasure to meet them here. Interior design and home textiles are closely related and new concepts can bring along improvement.”

Intertextile Shanghai Home Textiles – Autumn Edition was organised by Messe Frankfurt (HK) Ltd; the Sub-Council of Textile Industry, CCPIT; and the China Home Textile Association (CHTA). The next Autumn Edition will take place in August 2018, while the Spring Edition runs from 14 – 16 March 2018.

To find out more about this fair, please visit: www.intertextilehome.com.

For more information about Messe Frankfurt textile fairs worldwide, please visit: http://texpertise-network.messefrankfurt.com.

Messe Frankfurt Exhibition GmbH

Messe Frankfurt Exhibition GmbH

Messe Frankfurt Exhibition GmbH

Messe Frankfurt Exhibition GmbH

Messe Frankfurt Exhibition GmbH

Messe Frankfurt Exhibition GmbH

Messe Frankfurt Exhibition GmbH

Messe Frankfurt Exhibition GmbH

Messe Frankfurt Exhibition GmbH