Kelheim Fibres nominated for the “Cellulose Fibre Innovation of the Year 2021” award

Kelheim Fibres has been named as one of the finalists for the “Cellulose Fibre Innovation of the Year 2021” innovation award to be presented at the 2nd International Conference on Cellulose Fibres. With their plant-based and biodegradable fibres, the Bavarian viscose speciality fibres manufacturer presents a significant contribution to a plastic-free future for AHP (absorbent hygiene products). In contrast to other natural fibres, which are already available in fibre form and can only be treated on the surface, Kelheim’s technological flexibility offers the possibility to modify cross-sections and to introduce additives into the fibre matrix for intrinsic functionalisation. Through these modifications, Kelheim tailors its fibres specifically to the requirements of the individual nonwoven layers of the AHP and is able to achieve comparable performance values to synthetic fibres.

In addition to this, the speciality fibres from Kelheim offer a very attractive ratio of cost to performance in comparison with other fibres of natural origin such as organic cotton. They are therefore not only able to enhance the performance of the final products more effectively than other bio-based alternatives, but are, at the same time, financially attractive. "Consumers of absorbent hygiene products are often faced with a choice between sustainable solutions made from fibres of natural origin and products with better performance and good fluid management properties produced using synthetic fibres,“ says Dominik Mayer, from Kelheim’s R&D team. „Our goal is to offer products to the consumer which combine both sustainability and performance. Our sustainable and functional fibre technologies now make this possible.“

The project is a good illustration of the central element of Kelheim Fibres‘ innovation philosophy: the identification of unsolved problems in the market and the development of solutions in close cooperation with experts along the value chain using open innovation techniques. Fibres from Kelheim also offer a significant contribution to overcoming one of the biggest global challenges of our time, by reducing the amount of plastic waste in the environment. Step by step, or in this case layer by layer – Kelheim Fibres is moving towards a vision of a plastic-free future.

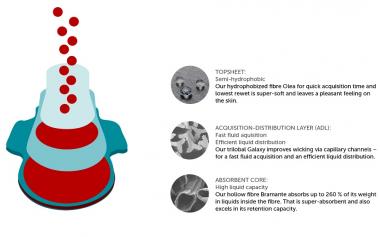

Kelheim’s developments include the hydrophobized Olea fibre (for fast acquisition and efficient transfer of liquid and for better rewet values in the topsheet) as well as the Galaxy® fibre (for an efficient and optimised distribution of liquids in the Acquisition Distribution Layer (ADL) via capillary channels) and the Bramante fibre (which can store up to 260% of its own weight of liquids in chambers inside the fibre). Kelheim’s fibres can also be processed in the textile sector, to enable solutions in the field of reusable hygiene products such as menstrual underwear. All these fibres are already commercially available. Kelheim Fibres is cooperating with an innovative AHP manufacturer and an innovative nonwoven supplier to incorporate the fibres into new end products.

Kelheim Fibres