MS PRINTING AT HEIMTEXTIL

- Focus on Productivity and Efficiency

MS Printing Solutions at the next Heimtextil will focus on presenting textile printing solutions to boost cost-effective and high-quality productions, answering to Industry leaders in home and contract textile who need: productivity, quality and beneficial production process.

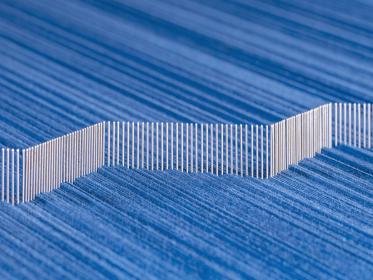

Attendees will see a JP4 EVO 3200 printer at work, with Bellagio reactive ink made by JK Group. This is one of MS' solutions which streamlines printing processes, reduces production times and maintenance costs, improving efficiency by:

- making the best use of production buildings, minimizing the space occupied by printers: JP4 EVO is compact and functional.

- taking full advantage of manufacturing-process, reducing downtime therefore improving productivity-performances: JP4 EVO can be fed by external roll unwinder ensuring timing optimization.

- using inks with a custom-made waveform, lowering the most common defects due to the interaction between ink and printheads, improving your productivity and competitiveness

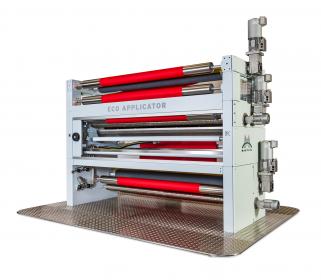

The show will be the occasion for the Technical and Sales Teams to illustrate all details which characterize Minilario. The printing machine, launched at the last ITMA, is the ideal choice for those searching for: flexibility, quality, speed, energy efficiency and sustainability, all in one.

The 64 print heads installed on the innovative printing carriage allow Minilario to reach the shocking but real printing speed of 18m/min, fitting the Home and contract textile demand of productivity and quality, applying a cost-effective production process.

The show will offer the opportunity to remark MS's sustainability commitment, started with #transparentaswater project based on the 100/90/10 paradigm aimed to engage the whole Textile Printing Industry in a big change. The commitment continued with MS’s adhesion to the “Sustainable Technologies” project launched by ACIMIT which selects textile machinery and systems manufacturers whose production specifications ensure a low environmental impact, combining sustainability and innovation. MS' printing machines may boast “Green Label” as “Suppliers of Sustainable Technologies” (come and visit us to go deeply inside our sustainability commitment).

Image & Communication JK Group S.p.A.