Reifenhäuser with solutions for films and nonwovens at K 2022

The Reifenhäuser Group will be represented with four booths at the world's leading trade fair for plastics processing, K 2022, from October 19 to 26. Under this year's Reifenhäuser motto "The Time is Now", the extrusion specialists will show producers of films and nonwovens solutions for the three major topics of the industry: sustainability, digitalization and productivity.

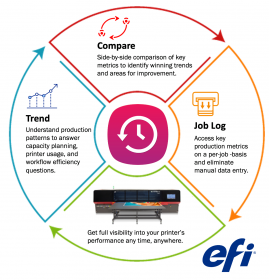

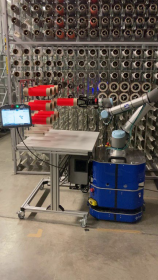

The main booth showcases the Reifenhäuser Blown Film, Cast Sheet Coating and Reicofil business units. With the help of machine exhibits, visual presentations and concrete solutions for end products, visitors will learn, among other things, how they can manufacture fully recyclable products economically, process recyclates safely, increase their output and network the entire production without becoming dependent on systems, specialists or manufacturers. To ensure smooth production even after purchase, Reifenhäuser Service shows how customers can get the best out of their Reifenhäuser products and increase their productivity with rework solutions, modifications, training programs and digital services.

The component specialists of the Reifenhäuser Extrusion Systems business unit will additionally present their portfolio at two other exhibition booths. Here, everything revolves around screws, barrels and extruders - and why, especially for processing recycled material, high-performance wear protection is essential for reliability and high economic efficiency. Reifenhäuser Extrusion Systems will also showcase its innovations for flat dies and coextrusion blocks and their coordinated interaction for maximum productivity.

In addition to its own booths, Reifenhäuser will also be present as a partner of the R-Cycle initiative as part of a joint pavilion on the open-air site in the so-called Circular Economy Forum. R-Cycle is a cooperation project of various technology companies and organizations along the entire life cycle of plastic packaging.

Aanother highlight for visitors to the Reifenhäuser trade fair booths is the opportunity to additionally participate in the in-house exhibition on October 20, 21 and 24 at the Reifenhäuser Technology Center.

Reifenhäuser GmbH & Co. KG Maschinenfabrik