Lotus Teknik Tekstil A.Ş.: Production line for biodegradable wet wipes by ANDRITZ

Lotus Teknik Tekstil A.Ş., Türkiye, has successfully started up a complete line to produce nonwoven roll goods for biodegradable, plastic-free wet wipes. This line has been delivered, installed, and commissioned by international technology group ANDRITZ.

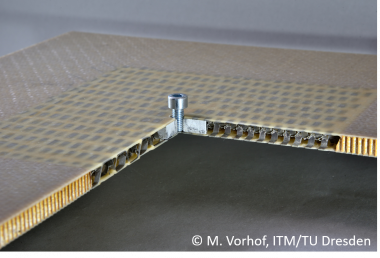

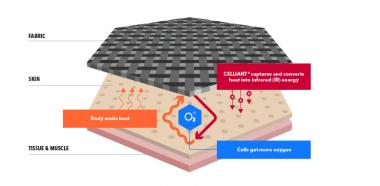

The neXline wetlace CP line combines the benefits of two technologies: wetlaid and spunlace. Natural fibers are processed gently to create a high-performance and sustainable wipe. This next-generation wipe, called Newipe®, combines the benefits of spunlace fabric, in particular remarkable strength in all directions, with the biodegradability and softness of a WetlaceTM fabric. It is produced with a lower carbon footprint, has a low lint rate, and does not generate dust during production.

Lotus Teknik Tekstil A.Ş. is a leading nonwoven roll good producer and a member of a group company. The group company consists of 4 companies that operate end-to-end manufacturing including nonwovens, cardboard packings, plastics, and finished wet wipe products. Headquartered in Istanbul, Sapro is the leader in Türkiye and one of the four leaders in the manufacturing of wet wipes in Europe. The company produces, converts, and supplies 161 million sheets of wipes per day for personal, household, and industrial use, exporting 70% of its production to 65 countries all over the world. Sustainability plays a prominent role in Sapro’s business strategy.