CHOMARAT extends its C-TAPE™ line with a new carbon tape

CHOMARAT, the composite reinforcement specialist, has developed a new unidirectional woven tape for its C-TAPETM line of products. Designed to meet the standards of industrial production, the new C-TAPE™ is reinforcing the foils of the “Figaro Beneteau 3”. These appendages improve the monohull’s stability and performance.

“For the series production of the foils, the Beneteau Group chose MULTIPLAST, the well-known builder of racing boats, which engaged the CHOMARAT Group to provide project support and achieve the best cost/performance balance,” explains Vincent CHOLVY, CHOMARAT’s Manager for the boating market.

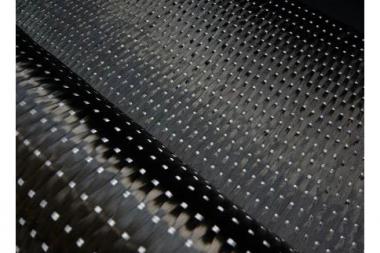

C-TAPE™, a high-performance carbon reinforcement with great design flexibility

C-TAPETM offers a lot of flexibility in terms of weight, width and construction. It has been optimized to facilitate series production, yet provide the foils with maximum performance.

The weft yarn developed by CHOMARAT makes the tape easy to handle and to work with. It is produced in 50-cm widths in order to adapt better to the mould, thus reducing both scrap and production cost.

“The project was an ambitious one,” says MULTIPLAST General Manager Yann PENFORNIS. “We had to reach a lower target cost, achieve a perfect foil shape, guarantee identical weight for all parts, and produce a set of foils per week over a period of one year.”

A reinforcement that facilitates flow in multi-ply carbon structures

Fifty plies of tape are used to make the foil so that it can resist high levels of stress and achieve optimal performance.

The specific structure of C-TAPETM facilitates resin flow throughout the thickness. The reinforcement provides the desired mechanical performance and also cuts down on production time.

The result is an ultra-innovative foil, both for its geometry and for the fabrication process (infu-jection) used.

“This new C-TAPE™ is the fruit of close co-operation between the MULTIPLAST and CHOMARAT development teams, and it rounds out our broad range of tapes. We are working on different fibres and adapting the widths to our customers’ processes in order to reduce costs,” concludes Vincent CHOLVY.

By the end of summer 2018, some one hundred foils will have been produced for assembly on the first 50 “Figaro Beneteau 3” monohulls.