SANITIZED (China) Ltd.: Featuring Advanced Antimicrobial Additives for Flexible Polymer Applications

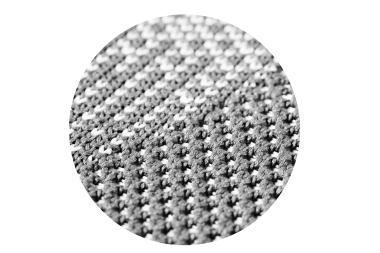

The global antimicrobial market is big business. Demand is strong due to increasing public awareness about contamination and infections, and by consumers’ desire for protective solutions. At Cinte Techtexil China 2018, taking place Sept. 4-6 in Shanghai, SANITIZED (China) Ltd. will be showcasing on Booth D25, Hall N1, its long-lasting Sanitized® Swiss antimicrobial protection for flexible polymer applications.

In recent years, regulatory developments have limited the available types of biocides that can be used to protect polymers and textiles from bacterial and fungal growth. For example, the biocide OBPA was widely used to protect PVC and other plastics from such issues in the past, but the European Union blocked OBPA from sale in January 2013, prompting producers to seek other options. Commonly used alternatives such as DCOIT, BBIT, zinc pyrithione or IBPC have their own limitations, related to their use in various flexible polymer applications.

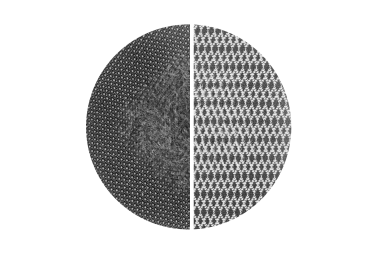

Outdoor applications in particular have seen an increase in performance requirements –– especially as regards antimicrobial effectiveness after exposure to water and ultraviolet light. Such additives also should not contribute to yellowing after UV exposure, but the available alternatives often fall short in this regard. And antimicrobial additives need to be able to meet the requirements for heat stability during the application process, while also avoiding initial discoloration and demonstrating compatibility with other additives in the formulation.

SANITIZED AG has developed a solution that addresses all these issues. Sanitized® PL 14-32 offers highly effective, long-lasting antimicrobial protection for flexible polymer applications. Besides thermal stability and compatibility with most formulations, Sanitized PL 14-32 provides high UV resistance and no yellowing after UV exposure, as well as good water resistance. It protects the target material against the unwanted effects of microbes such as bacteria, mold, mildew, yeast, pink stain and algae – all of which can destroy material, while also causing unsightly stains, cross contamination, odor development and biofilm formation. The product has been proven to deliver thermal and color stability, and efficient antimicrobial protection in several formulations. Further, it is supported under the EU`s Biocidal Products Regulation (BPR), and the U.S. Environmental Protection Agency has approved its active substances.