adidas: Journey to Circularity with FW 2021 Collection

2050 is the year when adidas plans to achieve climate neutrality. It’s also the year when it’s expected that our oceans will contain more plastic than fish, that is, if we don’t act now. Adidas' solution to help end plastic waste and achieve climate neutrality? Sustainable innovation.

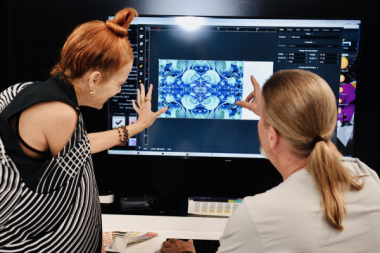

Last year adidas announced the Three Loop Strategy – their roadmap to help end plastic waste. At the heart of this is Circular Loop – Made To Be Remade.

The concept behind Made To Be Remade (MTBR) is simple: when one piece of plastic has fulfilled its purpose, it must be remade to fulfil another. Their attitude is that the end of one thing equates to the beginning of the next, and that their products’ lives can be extended by remaking them into new products.

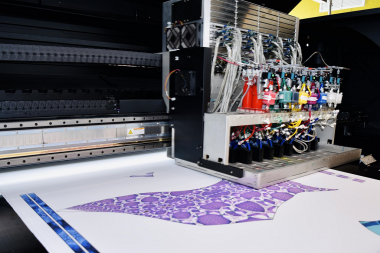

Adidas' Circular Loop creation process has come a long way since they introduced FUTURECRAFT.LOOP – their first running shoe made to be remade – in 2019. From what started as a beta program of just 200 pairs has developed into a concept within the business that spans across multiple categories and in April this year saw the first commercial launch – Ultraboost Made To Be Remade.

Ultraboost Made To Be Remade will see the next generation released in November this year (2021). The shoe will be created in part from the previous generation. Featuring a torsion bar that contains 25% reused content from the Futurecraft Loop Gen 2.

W21 will see another adidas icon join the MTBR family - Stan Smith Made To Be Remade. Just like the Ultraboost model, Stan Smith MTBR has been created entirely from TPU – from laces to midsole and everything in between.

Adidas’s best-loved Outdoor products are also receiving the MTBR treatment. Alongside Stan Smith MTBR, October will welcome the TERREX Free Hiker Made To Be Remade, featuring a TPU knitted upper and TPU outsole, making it the first TERREX hiking shoe to use the technology. The shoe will be accompanied by the launch of the TERREX Made To Be Remade Anorak – their second-generation prototype following on from the FW20 FUTURECRAFT.LOOP Anorak, which will be commercially available in 2022.

adidas AG