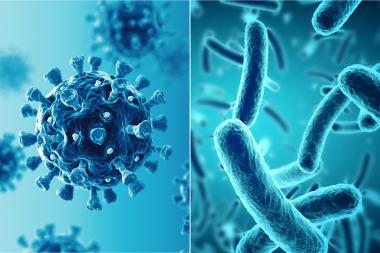

Antiviral and antibacterial zwissCLEAN masks® of zwissTEX

With zwissCLEAN® masks, zwissTEX is a pioneer among manufacturers of antiviral and antibacterial oronasal masks. Unlike conventional models they actively and highly effectively eliminate viruses and bacteria thanks to the latest textile technologies. This is made possible by an environmentally friendly finishing that foregoes the use of silver and zinc. "The formula physically interrupts the cell membrane of the viruses and bacteria - so no development of resistance is possible. In this way 99.9 percent of viruses and bacteria are eliminated within a very short time," says Maximilian Schönfließ - Business Development Manager of zwissTEX.

The zwissCLEAN MASK BASIC is particularly suitable when a mask is to be worn over a longer period of time - whether for school, concerts, trade fair visits or air travel. "The special feature of our zwissCLEAN MASK BASIC is that it can be worn for up to 12 hours without any problems due to the breathable material", says Schönfließ. "With it even sleeping is possible. And unlike disposable masks it can be washed up to 10 times at 30 degrees. Disposal by type is also possible".

The zwissCLEAN MASK COMFORT is recommended for daily protection at shopping, on public transport, at business appointments or similar events. It consists of a three-layer structure and combines efficient antiviral protection with long-term wearing comfort. The outer material and the integrated fleece promote protection against viruses and bacteria. The lower material made of organic cotton guarantees a lasting pleasant feeling on the skin. The mask can be washed up to 30 times, thus replacing up to 210 disposable masks and saving resources sustainably.