C.L.A.S.S.: Winner of the IMAGINING SUSTAINABLE FASHION competition announced

The winner of the IMAGINING SUSTAINABLE FASHION competition was announced during a webinar broadcast on March 30 at 4pm attended by Giusy Bettoni, CEO of C.L.A.S.S. Eco Hub, Anna Detheridge, President of Connecting Cultures, Dio Kurazawa, Founding Partner of The Bear Scouts, Stefania Ricci, Director of the Salvatore Ferragamo Museum.

Vishal Tolambia, 24, a graduate with an MA in Fashion Futures from the London College of Fashion and in Fashion Design from the National Institute of Fashion Technology India, is a Fashion Sustainability researcher and a multidisciplinary designer. In 2021, Vishal founded the organization Humanity-Centred Designs (HCD) with the aim of transforming "human-centred design into humanity-centred designs through sustainable practices to foster the Fashion Industry."

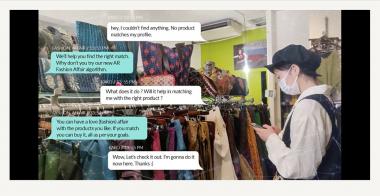

In his communication project, the "Fashion Affair" video proposes a speculative view of fashion dating - derived from dating apps - a tool to effectively evaluate brands and their products, in the form of augmented reality. The consumer is not only informed in real time about the brand and supply chain, but the app also becomes a platform for matching products based on individual sustainability goals and commitments. "Fashion Affair" also won the special social media contest open to the public among the finalists selected by the jury for being the most voted project by Instagram followers on C.L.A.S.S.' profile.

Vishal ranked first among the finalists selected by the international jury composed of:

- Anna Detheridge, Founder and President, Connecting Cultures

- Giusy Bettoni, CEO and Founder, C.L.A.S.S.

- Rita Airaghi, Director, Gianfranco Ferré Research Center

- Paola Arosio, Head of New Brands & Sustainability Projects, Camera Nazionale della Moda Italiana (The National Chamber for Italian Fashion)

- Jeanine Ballone, Managing Director, Fashion 4 Development

- Evie Evangelou, Founder and President, Fashion 4 Development

- Chiara Luisi, Sustainability Projects Coordinator, Camera Nazionale della Moda Italiana (The National Chamber for Italian Fashion)

- Sara Kozlowski, Director of Education and Sustainable Strategies, Council of Fashion Designers of America

- Dio Kurazawa, Founding Partner, The Bear Scouts

- Renata Molho, journalist and fashion writer, former editor-in-chief of L'Uomo Vogue and editor-at-large of L'Uomo Vogue, Vogue Italia, Casa Vogue

- Stefania Ricci, Director, Salvatore Ferragamo Museum.

C.L.A.S.S.