Monforts at Techtextil India

Monforts Textilmaschinen GmbH & Co. KG will be providing information on its extensive range of coating and finishing technologies for the production of nonwovens and technical textiles at the forthcoming Techtextil India exhibition.

“India is already a very important market for Monforts and there are exciting prospects ahead for Indian manufacturers of technical textiles, who are well positioned to capitalise on growth opportunities,” says Monforts Head of Denim Hans Wroblowski, who will be at the Monforts stand in Hall 4, booth C52 at the show. “India has one of the largest working-age populations in the world and a complete textile value chain for both natural and synthetic fibres.”

In addition, he adds, India’s government, through its Ministry of Textiles, has been actively promoting the growth of technical textiles through various programmes based on investment promotion, subsidies, the creation of infrastructure and the stimulation of consumption.

As a result, India’s Ministry of Textiles is forecasting that the growth of technical textiles in the country will be over 18% annually in the next few years, from a value of US$16.6 billion in 2018 to US$28.7 billion in 2021.

Value addition

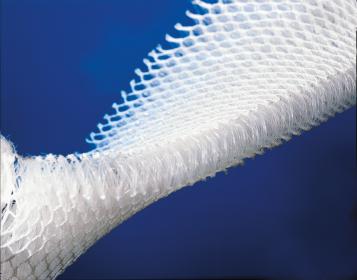

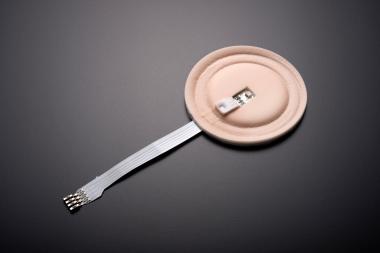

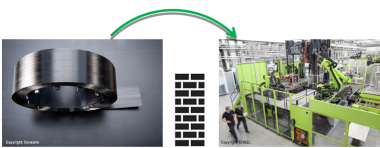

High value-added technical products such as wide-width digital printing substrates, carbon fabrics for high-performance composites, filter media, flame retardant barrier fabrics and heavy-duty membranes are now being coated on Monforts texCoat ranges and finished with the company’s industry-leading Montex stenters.

“Since we acquired the technology that our coating units are based on in 2015, we have made a lot of refinements,” says Hans. “All of these developments are reflected in higher coating accuracy and the resulting quality of the treated fabrics. At the same time, our latest multi-functional coating heads offer an unprecedented range of options, with a wide range of modules available.”

The texCoat user interface is now equipped with the unique Monforts visualisation system and the magnetic doctor blade has greater power reserves. Options include a carbon fibre-reinforced composite coating drum with a more scratch-resistant surface and maximum rigidity and remote control which simplifies exact adjustment for the operator.

Montex stenters in special executions are meanwhile ideal for the drying and finishing of both technical woven fabrics and nonwovens and characterised by high stretching devices in both length and width.

“The European-built Montex range of stenters has earned its leading position in the technical textiles market due to the overall robustness, reliability and economy of these machines,” Hans concludes. “Whatever the intended end-product – and we continue to discover potentially new areas in which technical textiles can be utilised all the time – we have the machine specification and know-how to turn ideas into reality. In India we also benefit from the strong sales and service support of A.T.E. Enterprises.”

Texchtextil India takes place alongside World of Composites at the Bombay Exhibition Centre in Mumbai from November 20-22.

A. Monforts Textilmaschinen GmbH & Co. KG by AWOL Media.