Dynamic Modifiers: Highest flame retardancy with new coating

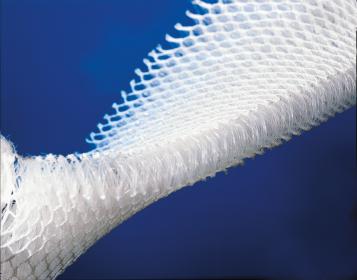

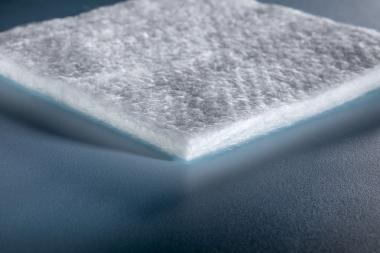

A new non-halogenated FR compound called PAL...VersaCHARTM can achieve a new level of flame retardant performance as a coating for nonwovens and technical textiles.

PAL...VersaCHARTM has been tested to 1,950°C – the highest to date – and shown to prevent all flaming drips of polymer. Char bodies form on the compound surface, protecting against flame creation and delaying heat transfer. Rapid self- extinguishing burn behaviour protects any underlying substrate to which it is adhered.

The compound has passed ASTM E84 (Class A) with a 15/10 rating, which includes ‘clean’ smoke generation of only 2.3% of the allowable ASTM smoke limits. In addition, the compound is light weight, at a specific gravity of 1.0, and 100% non-toxic in every respect, being free from heavy metals, halogens and VOCs.

Other properties include excellent cold crack performance, hydrophobicity, printability, extreme chemical resistance and the ability to be custom tailored for specific needs such as UV or antimicrobial performance, as volume warrants. The compound is also very competitively priced.

In addition to its use as a coating, PAL...VersaCHARTM compound can be produced as a flexible film or sheet and moulded to shape or over-moulded to most materials, including metal for corrosion resistance. As a polymeric compound it can be cast or calendered and typical durometers from 80-99A for flexible-to-high rigid formats are practical.

Separately, an adhesive has been created which bonds to many surfaces. In internal evaluations of two laminated plies of woven carbon fibre and two plies of glass fabrics, both passed a 60 second vertical burn with no ply separation, distortion or flaming drips from the adhesive.

Dynamic Modifiers envisages many uses for PAL...VersaCHARTM, from aerospace to the protection of rigid structural materials in building interiors etc.

Dynamic Modifiers

AWOL Media