Frühling, Sommer, Sonne: Gut geschützt genießen

Jährlich das gleiche Szenario: Irgendwann ist man des Winters überdrüssig. rühling, Sommer und Sonne können gar nicht schnell genug kommen. Und dennoch beginnen damit auch schon die ersten Bedenken: Wie schütze ich mich vor zu viel Sonne? Welcher UV-Schutz ist der beste? Schützt Kleidung effektiver als Sonnencreme? Mit dem nachfolgenden Text möchten wir Ihnen eine praktische und sinnvolle Anleitung für den Umgang mit Sonnenschutz geben. Damit Sie den Sommer in vollen Zügen genießen können.

Die Sonne ist der Lebensspender schlechthin. Doch zu viel Sonne schadet. Insbesondere ultraviolette Strahlung (UV-Strahlung) kann Augen und Haut nachhaltig schädigen. Je nach Hauttyp setzt eine Schädigung schneller oder später ein. Andererseits benötigen wir Sonnenbestrahlung, um Vitamin D zu bilden, das u.a. für die Knochenbildung wichtig ist. Generell jedoch gilt, dass Säuglinge gar nicht und Kinder nur eingeschränkt geschützt sind und deshalb nur beschränkt direkter Sonnenstrahlung ausgesetzt werden sollten. Erst ab einem Alter von rund 15 Jahren hat der Körper die vollen Schutzmechanismen gegen die schädliche UV-Strahlung entwickelt. Aber auch dann gilt, dass wir uns ohne UV-Schutz nur für eine begrenzte Zeit - je nach Hauttyp können das sogar nur wenige Minuten sein - im Freien bei direkter Sonnenstrahlung aufhalten sollten.

Was schützt mich vor zu viel UV-Strahlung?

Üblicherweise benutzen wir für das Sonnenbad Cremes mit UV-Schutz. Allerdings bieten selbst die stärksten unter ihnen – sogenannte Sunblocker – lediglich einen Lichtschutzfaktor (LSF) von 50. Und sie waschen sich im Wasser ab, werden beim Abtrocknen abgerieben und müssen für längeren Schutz mehrmals aufgetragen werden. Sonnenschirme oder Sonnenmarkisen schützen eingeschränkt vor indirekter bzw. reflektierter Strahlung.

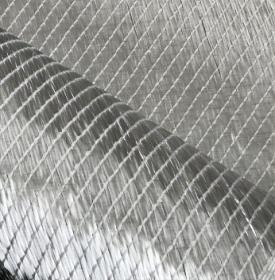

Dermatologen empfehlen deshalb als Sonnenschutz das Tragen von körperbedeckender Kleidung. Hier helfen schon die lange Hose, das langärmlige Hemd und eine Kopfbedeckung mit möglichst breiter Krempe oder für Kinder ein Nackenschutz. Auch die Kleidungsfarbe und -machart ist wichtig. So bieten dunkle Farben einen höheren Schutzfaktor als helle. Generell wird durch ein dichteres Material die UV-Strahlung am besten abgehalten. Synthetikfasern erzielen deshalb einen höheren UV-Schutzfaktor als Produkte aus Naturfasern. Zusätzlich sollten natürlich alle nicht bedeckten Körperbereiche mit einer Sonnenschutzcreme mit möglichst hohem UV- Schutzfaktor eingecremt werden. Darüber hinaus sollte man auch versuchen, sich selbst und gerade Kleinkinder mit einem Sonnenschirm zu schützen. Nutzen Sie also die Kombination aus Kleidung, Sonnenschirm und Sonnencreme.

Woran erkennt man moderne UV-Schutztextilien?

Am besten entscheiden Sie sich für Textilien, die einen hohen UV-Schutz garantieren. Um sicher zu gehen in welchem Maße ein Textil vor Sonnenstrahlen schützt, sollte darauf geachtet werden, ob und mit welchem UPF (Ultra Violet Protection Factor) ein Textil ausgelobt ist. UV-Schutztextilien schützen hoch effektiv vor UV-Strahlen. Sie bieten je nach Grundlage einen Schutzfaktor (UPF) von bis zu 80, womit Sie problemlos einen ganzen Sonnentag im Freien verbringen können.

„Um einen für den Verbraucher verlässlichen UPF zu ermitteln, müssen aber die besonderen Anforderungen berücksichtigt werden, denen ein Sonnenschutztextil beim Gebrauch ausgesetzt ist“, betont Silke Heidt, Leitung für UV-Schutz-Prüfungen in Hohenstein. Deshalb empfiehlt sie für den sicheren Aufenthalt in der Sonne, moderne UV-Textilien zu tragen, die nach dem UV STANDARD 801 geprüft sind. Seit 20 Jahren werden Textilien nach dem UV STANDARD 801 getestet, der eine effektive Prävention bietet, da die Textilien beim UV STANDARD 801-Testverfahren auch in nassem, gedehntem und gebrauchtem Zustand – also unter realistischen Bedingungen - geprüft werden.

Hohenstein