SHIMA SEIKI to exhibit at ITMA Asia and CITME 2020

Flat knitting solutions provider SHIMA SEIKI MFG., LTD. of Wakayama, Japan, together with its Hong Kong subsidiary SHIMA SEIKI (HonG KonG) LTD., will participate in the ITMA Asia + CITME 2020 exhibition to be held at the national Exhibition and Convention Center in Shanghai, China in June.

Through its exhibit theme—Step Beyond—SHIMA SEIKI will present its vision of the future, while addressing a variety of solutions for the new normal, including proposals in Factory Automation, Digital Transformation (DX), and various online solutions.

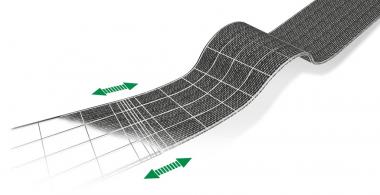

At ITMA Asia SHIMA SEIKI will be making proposals for factory automation centered around the special manufacturing capabilities of our WHOLEGARMENT® knitting machines. WHOLEGARMENT® knitwear can be knit in one entire piece without the need for linking or sewing, and allows for on-demand knitting. SHIMA SEIKI will present its WHOLEGARMENT® knitting technology in the form of two of the latest machines. The flagship MACH2XS is the one of most advanced flat knitting machines, featuring proprietary four-needle bed and Slideneedle™ technology combined with spring-type moveable sinkers and i-DSCS+DTC® Digital Stitch Control System with Intelligence and Dynamic Tension Control, and capable of all-needle knitting of WHOLEGARMENT® items. MACH2XS is presented in ultrafine 18L gauge, shown for the first time in China. Also shown for the first time in China, MACH2VS, a flexible V-bed machine capable of knitting WHOLEGARMENT® knitwear using every other needle, or conventional shaped knitting using all needles. It also features spring-type moveable sinkers and i-DSCS+DTC® Digital Stitch Control System with Intelligence and Dynamic Tension Control. MACH2VS is presented in ultrafine 18G with auto yarn carriers as a prototype option.

ITMA Asia will also be the occasion for a sneak preview of next-Generation 4-bed WHOLEGARMENT® knitting technology. The new machine is named SWG-XR, adopting the SWG moniker from the first-generation WHOLEGARMENT® knitting machine introduced back in 1995. The "X" represents 4 needle beds arranged in an Xshaped formation as per the original SWG-X machine, while "R" stands for Reborn and Revolution, referring to a renewal of SHIMA SEIKI's WHOLEGARMENT® knitting that raises the technology to unprecedented levels. By increasing the number of systems from 3 to 4 and featuring auto yarn carriers, SWG-XR allows even higher productivity and vastly improved range of knitting.

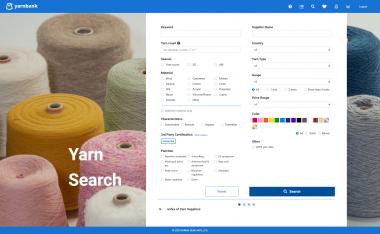

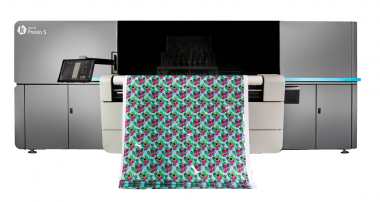

In order to further support efforts in DX in the fashion industry, SHIMA SEIKI has released three new online services over the past year which will also be showcased at ITMA Asia: 'APEXFiz™' subscription-based design software; 'yarnbank ™' digital yarn sourcing web service; and 'SHIMAnAVI™' e-learning service.

SHIMA SEIKI MFG., LTD.