CARBIOS and Hündgen: Supply agreement for PET biorecycling plant

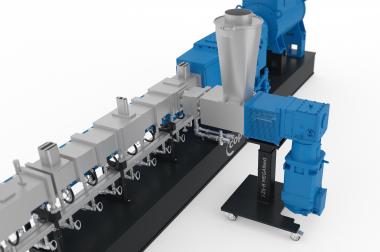

CARBIOS and Hündgen Entsorgungs GmbH & Co. KG (Hündgen), a waste management expert in logistics, sorting services and the recycling of recyclable materials from waste mixtures, announce the signing of a non-binding Memorandum of Understanding relating to the sourcing, preparation and recycling of 15kt/year of post-consumer PET waste using CARBIOS’ biorecycling technology at its first commercial plant in Longlaville, from end 2026.

The partnership will leverage Hündgen’s expertise and network in the sourcing and preparation of light packaging waste collected from German households. This PET waste will be prepared into flakes ready for biorecycling using CARBIOS’ enzymatic depolymerization technology, which produces food-grade PTA and MEG, further re-polymerized into PET.

The supply partnership with Hündgen contributes to securing the majority of CARBIOS’ feedstock needs for its first commercial plant in Longlaville, France. This plant will have a 50kt/year capacity when it will be fully operational and is currently under construction. This latest sourcing announcement comes in addition to previously announced agreements, such as with Landbell Group for food trays from Germany, and the winning CITEO tender for trays in France. The location of the Longlaville plant is strategically close to nearby waste supplies in Belgium, Germany and Luxembourg.

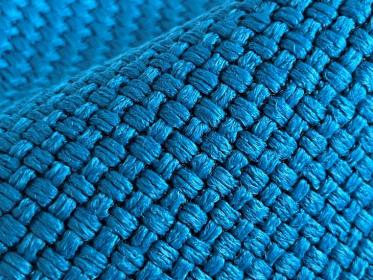

Through its enzymatic depolymerization process, CARBIOS can process all types of PET waste, including waste that cannot be recycled with current technologies. Multilayered, colored, and opaque packaging waste as well as polyester textile waste now have circular recycling solutions.

Carbios