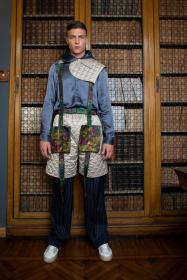

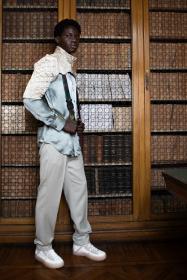

PREMIUM Group goes digital on FFW STUDIO

Live panels, future talks, brand experiences, stories, entertainment: from July 5th to 9th, the protagonists of the fashion industry will meet digitally for the first time on a common platform, the FFW STUDIO. Launched by the makers of Frankfurt Fashion Week and Europe's largest fashion fairs, PREMIUM, SEEK & Neonyt, the new content hub at www.frankfurt.fashion offers an individually designed program as an alternative to the physical event.

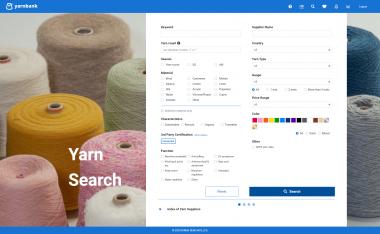

And the classic trade fair business will also find a digital representation this summer: Together with long-term partner JOOR, Anita Tillmann and team are presenting the PREMIUM + SEEK Passport platform this season. Here retailers can discover and order the collections of over 12,500 brands online and be inspired by various content formats.

FFW STUDIO broadcasts live from the conferences of Frankfurt Fashion Week, the Frankfurt Fashion SDG Summit presented by Conscious Fashion Campaign in cooperation with the United Nations Office for Partnerships and the conference "The New European Bauhaus - Workshop of the Future", organized by the Fashion Council Germany in cooperation with the Frankfurt Fashion Week. Both will take place for the first time as part of the Frankfurt Fashion Week. With over 130 speakers, the Fashionsustain conference is also a central component of the FFW STUDIOS.

PREMIUM Exhibitions GmbH