Sicomin: Collaboration with GREENBOATS® for natural fibre composite

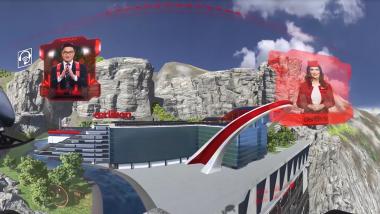

Sicomin announces its latest collaboration with GREENBOATS® as they deliver the first ever natural fibre composite (NFC) nacelle for an offshore wind turbine.

With more than 2.5 million tons of composite materials in use in the wind industry globally, and the first generation of wind turbines now approaching end of life, there is still a lack of well-established recycling options. GREENBOATS’ mission is to demonstrate how large-scale NFC structures in wind energy can lower energy consumption in manufacturing and significantly improve the sustainability of the composite materials used in the turbine.

In 2020, GREENBOATS was commissioned by a leading wind energy technology developer to design and manufacture a sustainable NFC nacelle. The resulting 7.3m long structure has a surface area of approximately 100m2 and was engineered by GREENBOATS to satisfy all DNV-GL load cases required for an offshore turbine nacelle, including 200km/h max wind loads and 2KN loads on the guard rails.

Sicomin’s market leading GreenPoxy® range met these challenging engineering requirements, with the company’s recently expanded manufacturing capability also matching the potential supply volumes required by wind turbine manufacturers.

Sicomin’s DNV-GL type approved bio-based epoxy was used to infuse BComp flax fibre reinforcements and balsa cores, with Sicomins’ intumescent weatherproof gelcoat applied on the outer surface. Cured panels were cut to shape, formed over a male plug and bonded together, before flax reinforcement plies, hand laminated with GreenPoxy resins and vacuum bagged, were added along all the panel joints lines. Finally, Sicomin’s highly UV resistant clear coating products were used to protect and enhance the finish of the flax fibre feature stripe details.

100% Marketing