C.L.A.S.S. welcomes Circular Systems into its Material Hub

After the C.L.A.S.S. recent evolution of its communication tools, they are really pleased to introduce Circular Systems as new C.L.A.S.S. Material Hub partner.

Circular Systems is a California based materials science company, focused on creating a net positive impact on environment, society and economy through innovation. Its circular plus regenerative technologies provide systemic solutions for transforming waste into valuable fibre, yarns, and fabrics for the fashion industry.

Textile waste and agriculture residues are a huge problem, often burned, left to rot in the fields, or sent to landfills creating massive amounts of CO2. Circular Systems is looking at these waste streams as valuable resources, turning problem into a solution by converting them into high value materials for the fashion industry. The “Lightest Touch™“ philosophy, defines their mission to retain maximum amount of embedded energy in waste inputs while creating the “highest-value outputs” with the lowest impacts. Integration of these technologies into global supply chains is key without compromising quality, thus extending the life cycle of these materials.

Circular Systems has three waste-to-fibre platforms that offer an efficient management of textile and agricultural waste:

- The Agraloop™ refines natural fibers derived from agricultural crops into textile-grade fiber called Agraloop™ BioFibre™. A NEW Natural Fiber mindfully sourced for circularity. With our specialized processing technique, cellulose fiber from stems and leaves are purified into soft fiber bundles ready to spin into yarns. The Agraloop™ processes leftovers from various food and medicine crops including, oilseed hemp/flax, CBD hemp, banana, and pineapple.

- Texloop™ Recycling produces high-quality GRS (Global Recycled Standard) certified recycled cotton fibre called RCOT™. Texloop™ preserves fiber quality for the next generation of recycled materials and blends with GOTS (Global Organic Textile Standard) certified organic cotton and Canopy approved man-made cellulosics to create near virgin quality yarns for knitting and weaving.

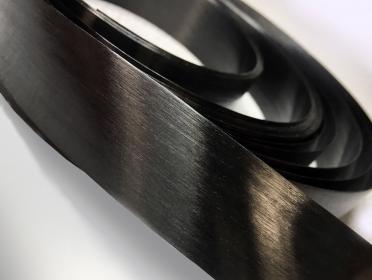

- Orbital™ hybrid yarns create high-quality materials with high-performance, using organic and recycled fiber inputs. Orbital's patent-pending technology produces inherent wicking and fast dry performance materials, even with 50%-70% natural fiber composition, eliminating the need for chemical finishes to create high-performance fabrics.

All Circular Systems yarns are GRS, OCS and/or GOTS certified and are in the process of developing their own Crop Residue Standard with Textile Exchange that would relate to the Agraloop™ platform technology.

C.L.A.S.S.