CHOMARAT presents its latest innovations at the 2018 JEC World

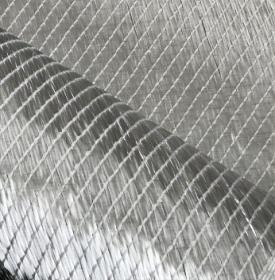

CHOMARAT, the composite reinforcement specialist group, is launching its multiaxial glass NCF for thermoplastic composites. The unique patented stitching yarn used can withstand processing temperatures to 400°C, making it an innovative industrial solution for thermoplastic composites and an alternative to the woven reinforcements used especially in the automotive sector. For the first time, CHOMARAT is also exhibiting a unidirectional carbon NCF reinforcement that is adapted to the productivity and performance requirements in the wind energy sector.

AN INNOVATIVE INDUSTRIAL SOLUTION TO REINFORCE AUTOMOTIVE THERMOPLASTICS

Thanks to a unique patented stitching yarn, the glass NCF reinforcement (G-PLY™) developed by CHOMARAT offers new possibilities in thermoplastic RTM and organosheet processes. “This is an especially innovative solution, utilizing stitching yarns that are compatible with processing temperatures to 400°C. These multiaxials improve the performance and provide a lot of construction freedom in terms of fibre orientation. These new design possibilities contribute to structural optimization. The quest for more lightweight vehicles, shorter cycle times and lower cost is a major issue for all builders,” explains CHOMARAT Automotive Market Manager Francisco De Oliveira.

This new heat-stable G-PLY™ reinforcement can withstand very high processing temperatures without deformation and provides optimal mechanical performance.

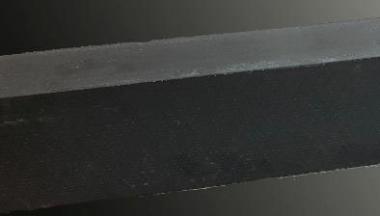

A CARBON UD TO REINFORCE EXTRA-THICK WIND TURBINE STRUCTURES

For the first time, CHOMARAT is exhibiting an infusion-moulded laminate made with 150 plies of its new unidirectional carbon C-PLY™. This 600g/m², high-permeability NCF can be used to create extra-thick structures, in particular the wind-turbine blade stiffeners, or spar caps. “Cost reduction is the challenge in the wind energy industry. Increasing the blade length by incorporating carbon stiffeners increases power, and so it also lowers the cost of the energy,” says CHOMARAT Wind Energy Market Manager Raphaël PLEYNET. The carbon UD developed by CHOMARAT provides a solution to achieve the goal to optimize the weight/power ratio. The UD’s high permeability reduces cycle times and lowers the blade production costs.

Professor Sung Ha from the University of Hanyang will give a conference on composite challenges in the wind energy sector at 11:30 am on Wednesday, 7 March 2018 at JEC World.

Established in 1898, CHOMARAT is an international industrial textile group, involved in three businesses: Composites Reinforcements, Construction Reinforcements, Coatings & Films–Textiles. The privately held company operates in France, Tunisia, the United States and China to service its global customers.

CHOMARAT leads a strong innovation strategy, rising to challenges, developing materials for the future. Hence, the Group invests in new technologies and enters into collaborative research programs with universities and technical centers worldwide.

CHOMARAT offers strong technical know-how and mastery of complex technologies in fields ranging from automotive, aerospace, sports, energy, marine, construction, and also in markets requiring creativity and expertise, like luxury goods.

Dorothée DAVID & Marion RISCH, AGENCE APOCOPE