Tatham: ‘Field to Fibre’ service for industrial hemp fibre production

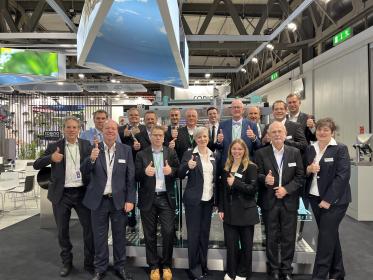

BTMA member Tatham has just delivered an advanced industrial hemp processing line to a major customer in Turkey and had many fruitful discussions about its machinery for the processing of natural staple fibres at the recent ITMA 2023 held in Milan from June 8-14.

The Bradford, UK-based company continues to equip mills around the world with staple fibre spinning and nonwoven technologies for manufacturing a wide range of products, while its TS system for drives and controls is suitable for retrofitting to all OEM textile machines, to provide user-friendly control systems with complete synchronisation and significant energy savings.

“We are currently fielding a lot of enquiries for technologies for the decortication, fibre opening and fabric forming of hemp,” said Tatham director Tim Porritt. “This is being driven by the sustainability of the fibre and concerns over climate change as brands seek solutions to meet their sustainability goals. As a result, there has been an explosion in the interest in hemp production, from farmers through to fibre production, and a wide range of new potential end-uses are being explored.”

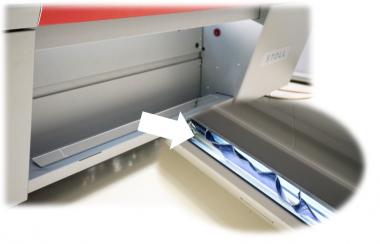

Tatham offers a complete ‘Field to Fibre’ service for industrial hemp fibre production and its decortication and cleaning process has a gentle opening action to maintain the fibre length, to make it suitable for subsequent processing.

BTMA