Lenzing Group: Difficult market environment and strategic success in 2022

- Revenue rose to EUR 2.57 bn, while EBITDA declined to EUR 241.9 mn

- Implementation of EUR 70 mn cost reduction program proceeding according to plan

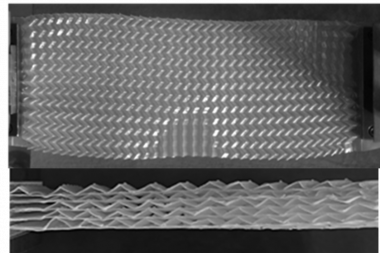

- Largest investment program in the company’s history including the lyocell plant in Thailand and the pulp mill in Brazil implemented on time and within budget

- Outlook: Lenzing expects EBITDA in 2023 to be in a range of EUR 320 mn to EUR 420 mn

The Lenzing Group was increasingly affected by extreme developments on the global energy and raw material markets in the 2022 financial year, in tandem with most of manufacturing industry in Europe. The market environment also deteriorated significantly in the third and fourth quarters, while worsening consumer sentiment placed an additional burden on Lenzing’s business growth.

In the year under review, revenue increased by 16.9 percent year-on-year to reach EUR 2.57 bn, primarily as a result of higher fiber prices. The quantity of fiber sold decreased, while the quantity of pulp sold rose. In addition to lower demand, the earnings trend particularly reflects the increase in energy and raw material costs. Earnings before interest, tax, depreciation and amortization (EBITDA) decreased by 33.3 percent year-on-year to EUR 241.9 mn in 2022. The net result for the year was minus EUR 37.2 mn (compared with EUR 127.7 mn in the 2021 financial year), while earnings per share stood at minus EUR 2.75 (compared with EUR 4.16 in the 2021 financial year).

Outlook

The war in Ukraine and the tighter monetary policy pursued by many central banks to combat inflation will continue to exert pressure on the global economy. The easing of China’s zero-Covid policy could lead to an unexpectedly rapid recovery. However, the IMF has warned that risks remain high overall and projects growth of 2.9 percent in 2023. Exchange rate volatility looks set to continue in regions that are important to Lenzing.

These challenging market conditions are also continuing to weigh on consumer confidence and sentiment in the sectors relevant to Lenzing. The outlook has improved slightly of late, with inventory levels returning to normal across the value chain. Nonetheless, subdued demand remains a source of concern for market players.

Inventories in the bellwether cotton market have diminished recently, although they remain above pre-pandemic levels. A decline in crops is foreseeable in the current 2022/2023 harvest season. The sharp rise in prices on the energy and raw material markets will continue to pose significant challenges for the market.

Overall, earnings visibility remains restricted.

In structural terms, Lenzing expects a continued rise in demand for environmentally friendly fibers in the textile and clothing industry, as well as in the hygiene and medical sectors. Thus, with its “Better Growth” strategy, Lenzing is very well positioned and will continue to drive growth in specialty products, while pursuing its sustainability targets including the transformation from a linear to a circular economy model.

In light of these factors and assuming a further market recovery in the current financial year, the Lenzing Group expects EBITDA in 2023 to be in a range of EUR 320 mn to EUR 420 mn.

Lenzing AG