DOMO Chemicals at the Wood Mackenzie European Nylon Conference

DOMO Chemicals, a global leader in the field of material engineering will discuss economic and environmental challenges at the 2019 Wood Mackenzie European Nylon Conference in Frankfurt am Main, Germany from March 5 to 7.

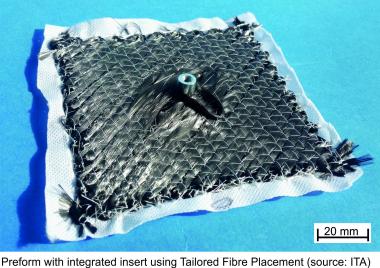

Ron Bult, Director of Global Sales of DOMO Engineering Plas-tics will highlight solutions based on ECONAMID®, a family of PA6 & PA66 compounds based on sustainable post-industrial feedstock derived either from film manufactur-ing or from fiber and yarn manufacturing. Depending on the applications and the desired level of physical and mechanical properties, DOMO can provide grades that are unfilled, mineral filled, glass-fiber filled, or carbon-fiber filled.

“DOMO is making major efforts to accelerate the development of sustainable solu-tions that bring value to our customers’ businesses, while acting responsibly towards the environment, employees and communities,” says Bult.

Also at the conference, Philippe Guerineau, VP Sales & Marketing in the company’s Nylon & Intermediates business unit, will join a panel discussion at the conference to discuss on the economic outlook and the future of the polyamide industry. DOMO will be holding consultations and exclusive events for its customers as well.

nylon

DOMO Chemicals