Messe Frankfurt (HK) Ltd: Intertextile Shanghai Home Textiles August 2020

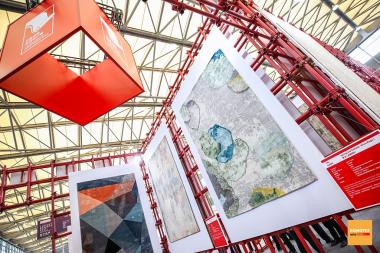

Intertextile Shanghai Home Textiles – Autumn Edition will return from 24 – 26 August 2020 at the National Exhibition and Convention Center (Shanghai), organised by Messe Frankfurt (HK) Ltd; the Sub-Council of Textile Industry, CCPIT; and the China Home Textile Association (CHTA). Stepping into its 26th edition, the trade fair will provide exhibitors the perfect opportunity to introduce new products and expand their distribution networks, as well as serving as a source of information and inspiration for professionals in every aspect of the industry.

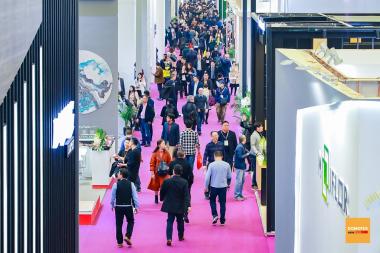

Celebrating its 25th anniversary last August, the Autumn Edition of Intertextile attracted 1,147 exhibitors from 27 countries & regions, as well as 35,390 trade buyers from 117 countries & regions (2018: 104), reflecting the increasing internationalism of Messe Frankfurt’s textile fairs in China, and the growing opportunities for international suppliers to meet a wide range of buyers in Shanghai. The trade fair’s capacity to attract large and diverse crowds has reinforced its status as the leading business platform for the home textile industry in the Asia Pacific region.

In the next edition, a large collection of quality Chinese companies, as well as premier overseas brands will once again present the entire spectrum of home and contract textile products including:

- Textile editors

- Whole Home Products

- Windows & Upholstery

- Bedding, Bath, Kitchen & Table

- Carpets & Rugs

- Sun-Protection

- Wallcovering

- Digital Print & Technics

- Fibers, Yarns & Chemicals

- Textile Designs

Opportunities abound in China’s home textiles market

“The upcoming Autumn Edition of Intertextile is set to offer suppliers and buyers the best platform to capture new business opportunities, especially as we continue to focus on bringing together more key players from the textiles, interiors, architecture and hospitality sectors in China and internationally,” Ms Wendy Wen, Senior General Manager of Messe Frankfurt (HK) Ltd said.

“Over the years, Intertextile has been evolving from a traditional trade fair to an immersive and interactive experience that inspires and engages attendees. Today, the fair is more than a business platform; it also delivers state-of-the-art home trends, valuable networking opportunities, as well as innovative and strategic solutions for brand development through a series of fringe programme events,” Ms Wen further explained.

As one of the selected exhibitors featured in the Talks & Tours series at the 2019 fair, Mr Thomas Luys, Sales Manager of LIBECO-LAGAE: “We had quite a diverse range of visitors, including an increase in e-commerce buyers, but also more traditional upholstery fabrics buyers. Our booth was also part of the Talks & Tours, so it was important to tell our story to a diverse range of visitors on this tour.”

To find out more about this fair, please visit: www.intertextilehome.com.

For more information about Messe Frankfurt textile fairs worldwide, please visit: http://texpertise-network.messefrankfurt.com.

Intertextile Shanghai Home Textiles, China, home textiles market Messe Frankfurt HK, Ltd

(c) Messe Frankfurt (HK) Ltd