Trützschler at Techtextil 2022

At this year’s Techtextil in Frankfurt/Main (June 21st to June 24th) Trützschler Nonwovens, Trützschler Card Clothing and Trützschler Man-Made Fibers present various new and proven solutions for the nonwoven, card clothing and man-made fiber sectors. Join us at booth D80 in hall 12.0!

Trützschler Nonwovens invites to talk sustainable fibers such as hemp or linen and out-of-the-box fibers such as nettle and pineapple fibers. Our solutions for manufacturing innovative nonwoven products include machinery and complete production lines for paper grade pulp, re-generated cellulose fibers, cotton and various other natural fibers.

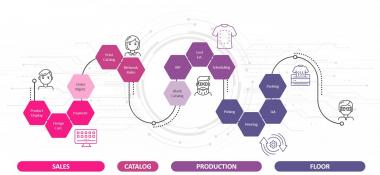

What happens when sustainable meets digital? Trützschler Nonwovens and software partner Proptium introduce T-ONE, our new digital working environment for both fiber- and polymer-based nonwoven producers. T-ONE supports routine tasks such as quality control and recipe management but also enables systematic line monitoring and data collection for T-ONE’s line optimizations.

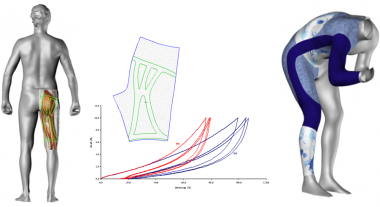

Trützschler Man-Made Fibers introduces the OPTIMA-based, versatile TEC-O40 and TEC-O80 systems for extruding and spinning industrial yarns (IDY). The modular OPTIMA platform is highly flexible and adaptable to manufacturing a broad spectrum of (semi-)industrial yarns from polyamide, polypropylene or polyester.

Trützschler