The countdown for ITM 2022 has begun

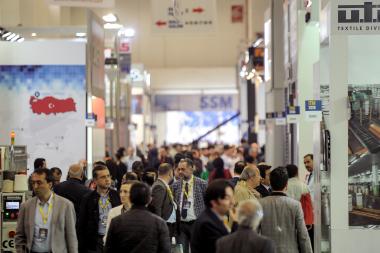

Organized by the partnership of Tüyap Fairs and Exhibitions Organization Inc. and Teknik Fairs Inc., the ITM 2022 International Textile Machinery Exhibition will be held at Istanbul Tüyap Fair and Congress Center on 14-18 June 2022. Hundreds of domestic and international exhibitors are looking forward to presenting their newest technologies for the first time at the ITM 2O22 Exhibition. Leading textile machinery manufacturers, global sector investors, and professional visitors are planning to come to the ITM 2022 Exhibition to examine the latest technologies closely.

Trade committees from dozens of countries are requesting to attend the ITM 2022 Exhibition, which is included in the ‘Domestic Organizations Covered by State Incentives’ list by the Ministry of Commerce. Bangladesh, India, Iran, Serbia, Czech Republic, Pakistan, Indonesia, Ethiopia, Malaysia, Mexico, Egypt and Vietnam are among the countries that requested procurement delegations.

The ITM 2022 Exhibition is of great importance for Turkish textile machinery and accessories manufacturers to increase their competitiveness in exports and to sign collaborations that will result in worldwide exports. Leading textile technology brands, which focus on product development and new productions during the pandemic conditions, are looking forward to the ITM 2022 Exhibition to present their products to the market and introduce them to their customers face to face. More than 300 manufacturers will make the world launches of their latest technological innovations at the ITM 2022 Exhibition.

ITM, Teknik Fairs INC