AVK Innovation Award 2022 to young engineers from ITM at TU Dresden

-

Award for near-net-shape 3D meshes for use in fibre-reinforced plastics

As part of the JEC FORUM DACH 2022, the AVK Innovation Awards were presented in Augsburg on November 29th. The innovation price in the category "Research/Science" (first place) was awarded to the team of scientists Dipl.-Ing. Dominik Nuss, Dr.-Ing. Cornelia Sennewald and Prof. Dr.-Ing. habil. Chokri Cherif.

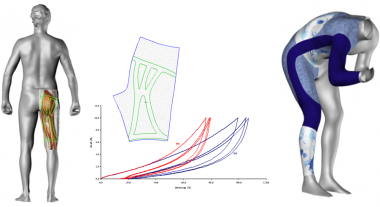

With the development of the pull-off-free Jacquard weaving technology including the technological know-how in the field of highly complex 2D and 3D fabric geometries, which has been established at the ITM of the TU Dresden for many years, Dominik Nuss has succeeded in including different yarn lengths locally into the fabric structure solely through targeted variation of the fabric weave. There-fore, it is now possible to produce completely new types of fabrics without additional draping, especially spherically curved fabrics, but also large-format spiral or even curved fabrics. The fact that the required near-net-shape geometry of the component to be reinforced can be reproduced with significantly reduced preforming steps is to be emphasized.

Continuous simulation aided engineering from CAD design to integrally woven 2D and 3D preforms by means of highly complex weave development for spatial constructions is a unique at the ITM, which was indispensable for the development of these promising woven high-tech structures. This technology is completely new and has never been carried out in this way before. The fabric structures are characterised by a high innovation level due to their geometric diversity and purposes. It can be used in numerous applications and further more contributes to the development of completely new fields of application. The technology can be implemented on all Jacquard weaving machines with only an additional device and the preform geometry is only determined by the control of the Jacquard machine. The preform geometry can be used in the full working width of the weaving machine.

Professor Chokri Cherif, Institute Director of the ITM, and his team are very pleased about these continuous research success in the constantly growing research field of 3D weaving technology, which are achieved at the ITM in close cooperation with industry and users. "This award is a special honour for our institute and confirms that the many years of our excellent research in the field of near-net-shape 3D weaving for the fibre-reinforced plastics sector plays a significant role and that we are making a significant contribution to the sustainable and resource-efficient production of lightweight structures with our development".

ITM/TU Dresden