Composites eröffnen neue Horizonte für die Möbelindustrie

Wie sieht der Möbelmarkt aus und welches Potential bieten Faserverbundkunststoffe für die Möbel von heute und morgen? Dieser Frage geht das AZL zusammen mit Firmen der Composite- und Möbelindustrie nach. Ergebnis wird ein Überblick über den aktuellen Markt und die bisher einsetzten Materialien sein sowie ein Ausblick auf zukünftige Massenanwendungen für Faserverbundkunststoffe (FVK). Die Studie ist offen für interessierte Firmen und startet mit einem Kick-Off-Meeting auf der Composites Europe in Stuttgart am 07. November 2018.

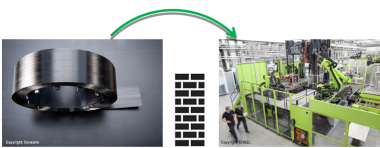

Möbel, ihr Design und Funktion haben sich in den letzten Jahrzehnten stark gewandelt: Vom massiven, lebensbegleitenden Möbelstück zum Trendgegenstand, vom handgefertigten Einzelstück zum Massenprodukt, vom Aufbewahrungsgegenstand zum smarten Alleskönner. Damit einher geht eine gesteigerte Vielfalt bezüglich des Designs und der verwendeten Materialen – und ein großes Potential für Composites, die zusätzliche Gestaltungsfreiheit und außergewöhnliche mechanische Eigenschaften bei geringem Gewicht bieten.

Studie bietet Überblick über Möbelmarkt und Alleinstellungsmerkmale von Composites

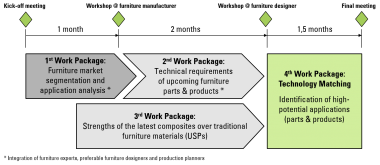

Um das Potential von Faserverbundkunststoffen systematisch zu identifizieren und diese gezielt und vermehrt in zukünftigen Möbelanwendungen einzusetzen, startet das AZL zusammen mit Firmen der Möbel- und Composite-Industrie eine Studie. Innerhalb von viereinhalb Monaten wird der Markt für Möbel segmentiert, Design- und Technologietrends herausgearbeitet und die technischen Anforderungen für Möbel und Möbelbauteile aufgeschlüsselt, um Anwendungen mit hohem Potential für Composites zu identifizieren. Übergeordnetes Ziel ist es, den Auswahlprozess und Bedarf des Möbeldesigners so zu verstehen, dass Composites gezielt als Alternative zu konventionellen Materialen in den Markt gebracht werden.

Virginia Bozsak, Technical Manager Composites bei ARKEMA Innovative Chemistry beteiligt sich an der startenden Studie: „Steigende Bevölkerungszahlen machen den Einsatz umweltfreundlicher Materialien unumgänglich und fordern Lösungen für die Wiederverwertung von Materialien. Zusätzlich müssen diese Materialien besondere Gestaltungsfreiheit ermöglichen, wenn sie in den schnell wandelnden Märkten, wie dem Möbelmarkt eingesetzt werden sollen. Arkema beantwortet diesen Bedarf bereits mit niedrigviskosem thermoplastischem Harz Elium®, das wie Duroplaste verarbeitet werden kann, um strukturelle und ästhetische Composite-Bauteile herzustellen. Mit der gemeinsamen Studie möchten wir für unser Material spezielle Anwendungen im Möbelmarkt identifizieren, um Kreativität und Designmöglichkeiten zu unterstützen und die Zukunft zu revolutionieren.“

Möbelmarkt ARKEMA Innovative Chemistry Faserverbundwerkstoffe Composites AZL Aachener Zentrum für integrativen Leichtbau rwth aachen

AZL Aachen GmbH