34th International Cotton Conference Bremen

- Deep Insights into the Multifaceted World of Cotton

- Quality, Innovation and Digitalisation are Crucial

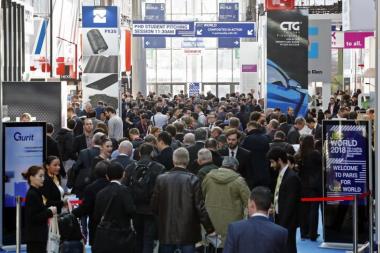

From the 21st to the 23rd of March, the international cotton industry came together in the historic Bremen Town Hall, under the motto "Cotton Insights". More than 500 participants from almost 40 countries came to exchange views on the latest trends in the natural raw material as part of the conference organised by the Bremen Cotton Exchange in cooperation with the Fibre Institute Bremen. The 34th International Cotton Conference provided a varied, in-depth programme which addressed the current and burning issues within the industry.

Summarising his visit to the conference, Kai Hughes, Executive Director of the International Cotton Advisory Committee (ICAC) in Washington said “The Bremen Cotton Conference is unique because it brings the diverse world of cotton together in one place. It is always a great opportunity to learn about the latest innovations, talk to cotton merchants and get an overview of the industry".

Sustainability and Cotton

This year, the conference developed into a whole week of diverse events around the entire cotton supply chain. With the “SUSTAIN” event, which was organised in cooperation with the Weser-Kurier newspaper, it was possible to build a bridge between the issue of sustainability and the end consumer.

With the focus on Africa, the emerging continent, which also has a special significance for cotton, became the centre of attention.

In his opening speech, Henning Hammer, President of the Bremen Cotton Exchange, made it clear that sustainability is also of great importance during the Cotton Conference: "The three pillars of sustainability – the environment, the economy and social issues – were already playing a role in the cotton industry when the word sustainability was far from being on everyone's lips.

Many changes that are being demanded in the sense of responsible agriculture and responsible trade take their time, many are already in the starting blocks and a lot already exists. We have a very alert, active agricultural research worldwide."

The Keynotes

The keynote session, moderated by the journalist Lisa Boekhoff from the newspaper Weser-Kurier, gave participants an overview, with an informative analysis of the current cotton situation. Kai Hughes, executive director of ICAC, emphasised in his keynote address the need to provide credible facts and figures which should be the basis for the entire supply chain. The marketing of cotton and changing consumer habits in a globalised and digitalised world were the subject of lectures by Mark Messura, Cotton Incorporated and Robert Antoshak, Olah Inc. Eugen Weinberg and Michael Alt from Commerzbank took a look at the raw material from a stock market perspective.

Traceability and Digitalisation

Digitalisation is also a cross-cutting issue that runs through the entire supply chain of the cotton industry. In his opening speech, Prof. Axel S. Hermann, Head of the Fibre Institute Bremen, emphasised the importance of digitalisation for the industry. “It enables new approaches in cotton cultivation and textile processing, but also influences consumer behaviour and thus the necessary changes in the textile industry.” The focus is on the status quo of the implementation, as well as the opportunities and risks of digitally controlled, vertically integrated procurement and sales processes and the associated challenges at retail level.

Another current topic is traceability, which is also closely linked to sustainability. More and more buyers want to know whether their suppliers are meeting the promised sustainability criteria for their products, also textile products. Consequently, the conference presented various techniques for testing the authenticity of a cotton provided in the finished textile, such as DNA testing, fingerprint analysis technique, marker methods and block-chain processes.

Cotton Quality

In addition to current subjects such as digitalisation and traceability, questions of cotton quality have traditionally been an essential element of the Cotton Conference, which was further reinforced this year with the "Spinners Seminar". The spinning mill seminar, which was carried out by the Cotton Exchange and the Fibre Institute in cooperation with the ITMF and IVGT associations, far exceeded expectations.

More than 70 participants discussed the handling of impurities in supplied cotton in the manufacturing process.

In addition, in a high-level expert session, there was an exchange of the latest research results which determine the future of cotton production and the processing of cotton into innovative products.

BREMER BAUMWOLLBÖRSE