Hohenstein and Presize partner for more sustainability for online shopping

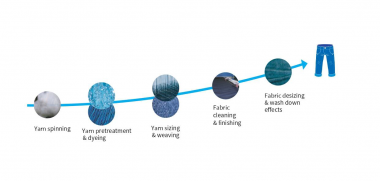

Hohenstein, a leading specialist in fit and pattern engineering, has joined forces with digital size pioneer, Presize. The partnership now offers a variety of business services, including reliable size tables and digital scaling, that empower online retailers to automatically recommend appropriate garment sizes.

Merging traditional size tables, reliable garment fits and digital body measurements with smartphone technology reduces the number of returned online purchases. Proper fit also reduces waste, lowers footprint and bolsters customer loyalty.

“The better a brand understands sizes, fits and target groups, the more accurately they can automate size recommendations. We help brands meet the different requirements of various sizes, so the fit is comfortable across customer ranges, collections and suppliers,” states Simone Morlock, Head of Hohenstein’s Digital Fitting Lab.

This size and grading advice is now underpinned by digital measurement services and technology based on artificial intelligence. “All it takes to work out the right size, based on a user’s individual body measurements, are some quick questions regarding their age, height and weight, plus an optional video to take measurements. We use an algorithm that learns as it goes along, and this improves the advice given on sizes with each order or return,” states Presize co-founder and CEO, Leon Szeli.

Join the free webinar on “Hohenstein Meets Presize - How sizing fundamentals and reliable fit can increase the effectiveness of smartphone body measurements and reduce eCommerce returns” on March 24, 2022.*

*Click here for more information.

Hohenstein