Nanomodified polymerstent: Novel technology for tumour therapy

- Electromagnetically heatable nanomodified stent for the treatment of hollow organ tumours wins second place at the RWTH Innovation Award

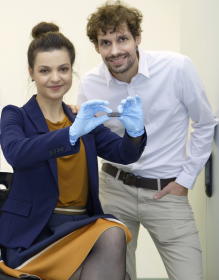

Almost every fourth person who dies of cancer has a hollow organ tumour, for example in the bile duct or in the oesophagus. Such a tumour cannot usually be removed surgically. It is only possible to open the hollow organ for a short time using a stent, i.e. a tubeshaped prosthesis. However, the tumour grows back and penetrates the hollow organ through the stent. Ioana Slabu from the Institute of Applied Medical Technology and Benedict Bauer from the Institut für Textiltechnik of RWTH Aachen University have now developed a novel technology for the therapy of hollow organ tumours, which was awarded second place in the RWTH Innovation Award. This involves a polymerstent that contains magnetic nanoparticles. When electromagnetic fields are applied, these nanoparticles lead to a controlled heating of the stent material and thus of the tumour. Because the tumour reacts much more sensitively to heat than healthy tissue, it is destroyed and the hollow organ remains open. Thus, the stent develops a self-cleaning effect.

Ioana Slabu of the AME explains: "Not only can we drastically reduce treatment costs, but above all we can provide relief for millions of patients worldwide.

A manufacturing process and proof of concept for magnetic hyperthermia are already in place. This novel technology has a very high development potential because it can also be used for tumours in other parts of the body such as the prostate, stomach, intestine or urinary bladder or for cardiovascular diseases.

The AiF/IGF project started under the project title "ProNano" funded by BMWK. Now the approval for the follow-up project "ProNano2" has also been received. The approved project is called: "Validation of the innovation potential of heatable stents for heat-induced treatment of cavity tumours" and is funded by BMBF in course of the VIP+ program. With the Clinic for General, Visceral and Transplantation Surgery of the University Hospital Aachen and the Institute for Technology and Innovation Management at RWTH Aachen University, the consortium is enriched by clinical and economic expertise. Every year, RWTH Aachen University honours particularly innovative university projects with the Innovation Award. Professor Malte Brettel, Prorector for Business and Industry, presented the certificates to four outstanding projects as part of RWTHtransparent.

stent cancer nanotechnology RWTH Aachen ITA Institute of Applied Medical Technology Institut für Textiltechnik der RWTH Aachen University

ITA – Institut für Textiltechnik of RWTH Aachen University