GKD auf der INDEX mit neuen Gewebetypen und Weiterentwicklungen

Zur INDEX in Genf, vom 19. bis zum 22. Oktober 2021, präsentiert die GKD Gruppe (GKD) ihre Vliesstoffformierung, -trocknung und -verfestigung sowie Polymerfiltration. Im Mittelpunkt des Messeauftritts zur einer der größten globalen Vliesstoffmessenm stehen neue Produkte für Meltblown-, Airlay- und Spunbond-Vliesformierung. Außerdem stellt die technische Weberei dem Fachpublikum die Weiterentwicklung der in anspruchsvollen Thermobonding-Prozessen seit 2016 bewährten Glashybrid-Gewebebänder vor. Auch maßgeschneiderte Filtermedien aus Metallgewebe für Zentralfilter, Spinnbalken und Anblassiebe für die Polymerfiltration werden auf der Messe präsentiert.

Airlay- und Meltblown

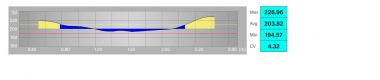

Mit dem neuen Prozessbandgewebe CONDUCTIVE 2215 ergänzt GKD das Spektrum an Bändern für die Vliesformierung. Diesen Gewebetyp kennzeichnet eine Kreuzköperbindung aus speziellen Polyester-Filamenten. Durch ein Zusammenspiel von Materialwahl, Filamentdurchmesser, Bindungstechnologie und Luftdurchlässigkeit entsteht eine optimale Gewebeoberflächentopografie für die Vliesablage.

Spunbond-Vliesformierung

Mit CONDUCTO® 7690 präsentiert GKD auf der INDEX eine Gewebekonstruktion aus Polyester-Monofilen und metallischen Multifilen. Die webtechnisch auf der Bandrückseite eingebrachten Metallfasern haben keinen Kontakt zum Produkt. Das qualifiziert diesen Gewebetyp auch für die risikofreie Produktion anspruchsvoller Medizin- oder Hygieneprodukte. Gleichzeitig gewährleistet das ebenso robuste wie flexible Garn aus Edelstahlfasern eine bis zu zehn Mal höhere Ableitung elektrostatischer Aufladung als herkömmliche Bänder.

Converting: Spiralbänder

Mit Spiralbändern aus eigener Fertigung bietet GKD eine Lösung für Anwendungen, die beispielsweise für breite oder schnelllaufende Anlagen der Hygienevliesindustrie geeignet sind.

Thermobonding: Antihaftbeschichtetes Glashybrid-Gewebe

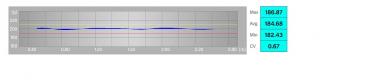

In Doppelbandöfen sind die Glashybrid-Gewebebänder bei der thermischen Verfestigung von hoch voluminösen oder stark verdichteten Produkten geeignet. Querstabilität und vollständige PFA-Beschichtung qualifizieren sie für stark klebende Produkte ebenso wie für Anlagen mit großer Arbeitsbreite oder Produkte mit starken Schrumpfkräften. Als einlagige Gewebekonstruktion mit Edelstahldrähten in Schussrichtung und Kettseilen aus Glasfaserlitzen sind sie außerdem energieeffiziente Leichtgewichte - wahlweise magnetisch oder nichtmagnetisch ausgelegt.

Polymerfiltration: Lange Standzeiten durch Metallgewebekonstruktionen

Die prozessabhängige Gewebeauslegung gewährleistet hohe Schmutzaufnahmekapazität, feine Abscheideraten und geringe Verblockungsneigung. Langfilter oder Ronden aus anwendungsindividuell abgestimmten Gewebelagen optimieren im Spinnbalken die Filtration des Schmelzflusses.

GKD / impetus.PR