Mimaki to launch the 330 Printer Series

- Mimaki’s Newest Product Series to Transform the Sign Graphics and Textile Markets with Improved Efficiency and Quality

- Mimaki to launch the 330 Printer Series and the new entry-level cutting plotter series, the CG-AR

Mimaki Europe today announces a brand-new large format inkjet printer series, the 330 Series, including the JV330-160, CJV330-160 and TS330-1600, as well as a new range of CG-AR cutting plotters. Launched during the company’s Global Innovation Days event, the 330 Series leverages Mimaki’s cross-platform strategy, to offer a high-end yet cost effective printing solution across several sectors. Similarly, the CG-AR Series offers users new workflow enhancing, entry-level cutting plotter technologies available in three sizes. Both launches align with Mimaki’s objective to grow both its high-end and entry-level product range, to further encourage and support customers expanding and improving upon their printing services and product offering.

Introducing Mimaki’s latest printers – the 330 Series

Following on from the success of the 100 and 300 Plus Series, the 330 Series was developed to offer mid- to high-end printing models, focusing on high image quality and productivity. As a company renowned for its high-colour range, Mimaki’s newest printers can achieve high resolution, durable prints for both the Sign Graphic and Textile industries.

The eco-solvent inkjet printers, the JV330-160 and CJV330-160, deliver the high-standard of colour required for indoor and outdoor sign graphics through the new “Deep Color Natural” input profile, offering eye-catching and vivid solid colours, natural skin tones as well as deep reds and neutral greys. With printing speeds of 21.0m2/h during standard mode while using 4 colours, this printer is ideal for print jobs that require quick delivery. The in-built cleaning mechanisms and monitoring features ensure an efficient workflow and allow for longer running times.

Both models feature a newly designed unwinding system that allows three rolls of media to be loaded simultaneously, greatly reducing the time and manpower required to change print media. One operator can bring the desired media into position simply by turning the media changer. Another standard feature is an “XY slitter” - a highly precise cutting technology, which provides in-line X-axis and Y-axis sheet-fed cutting. This eliminates the unwinding and rough cutting from the workflow, helping printers to significantly speed up and streamline the post-process, with less interference needed.

The print-only model JV330-160 as well as the integrated printer and cutter CJV330-160 will be available globally in April 2022.

In addition to the Sign Graphics solutions, Mimaki has also released the TS330-1600, a sublimation transfer inkjet printer, for the textile industry. Enabling both high production and high image quality, and equipped with new functions to improve stable operation, the TS330-1600 can achieve a printing speed of 69m2/h in Draft mode with a 4-colour ink set, with the fastest mode reaching up to 135m2/h. The newest cleaning mechanism applies a cloth wiper that removes unwanted ink from the nozzle surface, reducing ink splatter and improving the overall upkeep of the machine.

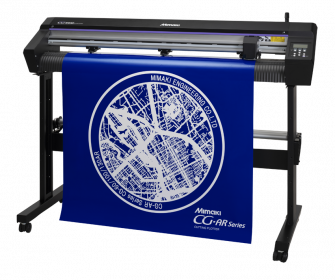

Increasing efficiency with entry-level CG-AR plotting cutter series

Alongside the 330 Series, Mimaki has also launched the CG-AR Series plotting cutters. Available in three different sizes (CG-60AR, CG-100AR and CG-130AR), these plotters go above and beyond current entry-level options available today. Recognising customer demand of shorter delivery times, these cutters provide increased speed and accuracy, all with user-friendly operability. In addition, the cutters have the ability to handle a diverse range of materials, such as PVC, fluorescent and reflective sheets.

Mimaki Europe BV