Hohenstein India inaugurates new leather & footwear laboratory

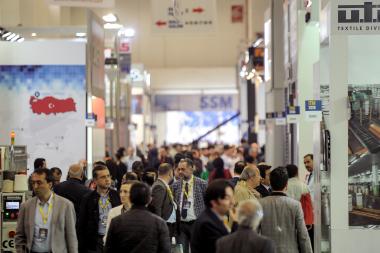

How can economic success be linked with product responsibility and more sustainability? More than 300 players and Hohenstein customers in the Indian textile industry accepted Hohenstein India's invitation to attend the Global Sustainability Conference in Gurugram, India, on November 10, 2022, and to obtain possible solutions to this question. The following day, numerous invited guests gathered at the Hohenstein laboratory site in Gurugram for the ceremonial inauguration of a new leather & footwear laboratory, the first of its kind in the global Hohenstein Competence Network.

With the ceremonial opening by Prof. Dr. Mecheels, Dr. Christof Madinger, COO Hohenstein HTTI and Dr. Helmut Krause, Hohenstein Technical Director Softlines & Shoes, the starting signal was given for the new leather & footwear laboratory at the laboratory site in Gurugram on November 11, 2022. During tours, visitors were able to get a personal impression of the future focus of work on site: testing for harmful substances in accordance with the LEATHER STANDARD RSL and the subsequent certification of leather and footwear products in accordance with the OEKO-TEX® LEATHER STANDARD will in future ensure a lower market risk for brands, retailers and suppliers and comprehensive and reliable safety for consumers.

Hohenstein