BASF Acquires 3D Printing Service Provider Sculpteo

- Acquisition drives market growth

- Additional sales channel for BASF customers and partners

- Access to new materials and technologies for customers of BASF and Sculpteo

To continue to expand its position as a leading service provider in the additive manufacturing sector, BASF New Business GmbH has formally agreed to acquire the online 3D printing service provider Sculpteo. The agreement was signed on November 14, 2019 and is expected to become effective in the next few weeks pending regulatory approval by the relevant authorities. The acquisition of the French 3D printing specialist based in Paris and San Francisco will enable BASF 3D Printing Solutions GmbH, a wholly-owned subsidiary of BASF New Business GmbH, to market and establish new industrial 3D printing materials more quickly. Sculpteo’s management team fully supports the acquisition and will remain in place to provide customers and partners with this expanded service spectrum.

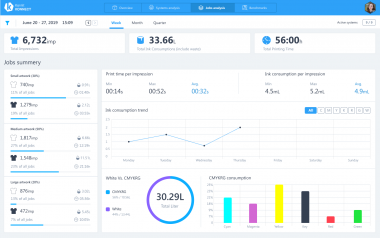

For around a decade already, Sculpteo has operated an online platform with integrated production for the manufacturing of prototypes, individual objects, and serial production components with a range of different additive manufacturing technologies. Customers in various industrial sectors around the world use the Sculpteo service to produce new components rapidly and reliably.

BASF will develop the existing Sculpteo 3D printing platform further into a global network. For customers and partners, BASF 3D Printing Solutions will thus be able to offer an additional channel for marketing their services and expanding their own customer bases.

"Through the acquisition of Sculpteo, we can provide customers and partners with even faster access to our innovative 3D printing solutions. In addition, our customers will benefit from an extended range of services”, explains Dr. Dietmar Bender, Managing Director BASF 3D Printing Solutions. “Together with Sculpteo, we are pursuing our goal of establishing additive manufacturing as a proven technology for industrial mass production", says Bender.

Combining the strengths of both companies will provide Sculpteo's existing customers with access to a more extensive portfolio of 3D printing materials. "We are excited to join the BASF team and thus benefit from BASF’s outstanding R&D to provide our customers with innovative solutions”, says Clément Moreau, CEO and Co-Founder of Sculpteo. Moreau will stay with Sculpteo as CEO.

Beyond this, the Sculpteo Design Studio and BASF’s technical experts will collaborate to be able to support customers in their 3D printing projects from the early planning phase right through to the final printed part. This will enable BASF to offer its customers end-to-end industrial 3D printing solutions.

BASF Marketing & Communications Manager