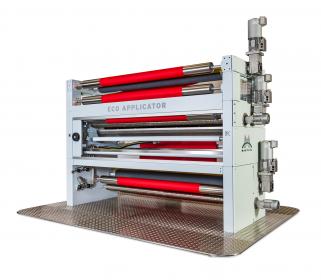

Saurer’s highly efficient FusionTwister at ShanghaiTex 2019

In its 19th year, the international textile industry exhibition ShanghaiTex will take place from 25 to 28 November 2019. Saurer Twisting Solutions would be delighted to welcome customers and visitors to Saurer's Stand D40 in Hall E1. The focus is on the highly efficient FusionTwister for staple fibre yarns.

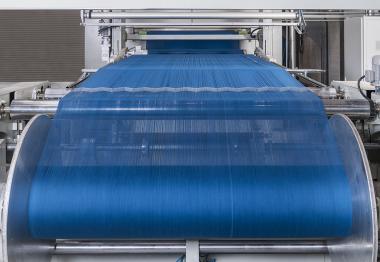

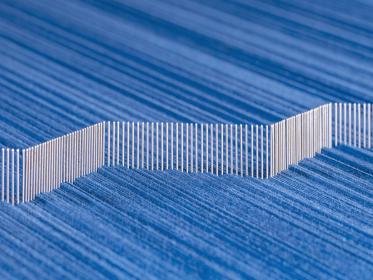

The FusionTwister sets the benchmark for the cost-effective production of two-for-one twisted staple fibre yarns. In order to achieve this, we have taken into account the three main factors affecting our customers’ profitability, namely energy, economics and ergonomics.

The machines’ reliably low energy consumption is an important characteristic for decision-makers to take into account. Achieved by means of an optimised spindle drive as well as a great variety of spindle and feeding sizes for all kinds of applications, it is the main element in the equation of production costs.

Power consumption and costs are closely related, with energy efficiency positively influencing the return on investment, since it is daily challenge to process the maximum feeding weight while keeping electricity usage at a comfortable level.

The machine’s short set-up times, fast air threading and easy handling were key considerations with regard to optimising ergonomics.

Saurer AG