PCMC and Hudson-Sharp help outfit Aspen Press & Packaging’s packaging division

Paper Converting Machine Company (PCMC) and Hudson-Sharp, part of Barry-Wehmiller’s Converting Solutions platform, have made significant contributions to Aspen Press & Packaging’s new flexible packaging division. Based in Salt Lake City, the packaging company has installed a 10-color, 52-inch Fusion C flexographic printing press from PCMC and two Ares 400-SUP stand-up pouch machines from Hudson-Sharp.

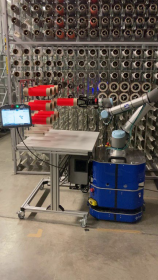

PCMC’s Fusion C is a central impression (CI) press that combines the features and advantages of both inline and CI presses. It allows for quick setups and efficient runs, and is the only CI press manufactured in North America.

Also incorporated into Aspen Press & Packaging’s new flexible packaging division are two Hudson-Sharp Ares 400-SUP stand-up pouch machines. Recognized as state-of-the-art in quality, speed and accuracy, the Ares 400-SUP has a compact footprint, and offers quick changeovers and the ability to run a variety of substrates with ease, including recycle-ready PE, biodegradable films, laminated films and paper.

Paper Converting Machine Company PCMC Hudson-Sharp packaging Paper Packaging digital printing

PCMC, Barry-Wehmiller