Kornit Digital and Fashion-Enter Bring Fashion and Textile Production Back to the UK with Sustainable, On-Demand Digital Manufacturing

- Unveil UK’s first-ever sustainable Fashtech Innovation Centre, displaying mass customization capabilities empowering designers, apparel brands, and other creatives

Kornit Digital Ltd. (NASDAQ: KRNT), a worldwide market leader in sustainable, on-demand digital fashionx and textile production technologies and Fashion-Enter - a social enteprise, which strives to be a centre of excellence for sampling, grading, production, and for learning and development of skills within the fashion and textiles industry – today announced a first-of-its-kind Fashtech Innovation Centre in London. Aimed at bringing on-demand fashion and textile mass customization back to the UK, and unveiled on March 3rd and 4th, 2022 at Fashion-Enter's state-of-the-art training and manufacturing site, the Centre is fully supported by Kornit Digital's revolutionary, direct-to-fabric and direct-to-garment digital production solutions.

According to Kornit Digital’s Impact and Environmental, Social and Governance (ESG) report, 30 percent of textile production is overproduction, while 95 percent of water waste is created as companies globally look towards more sustainable futures with customized, creative, and real-time offerings. Using proprietary streamlined, eco-friendly digital production technologies, Kornit Digital is transforming the fashion industry with more efficient and sustainable processes. According to the same report, by 2026, the Company’s systems will use up to 95 percent less water, 94 percent less energy and produce 83 percent less greenhouse gas emissions.

In addition to highlighting production capabilities that minimize carbon footprint, the Fashtech Innovation Centre serves as a prototype for brands and fulfillers seeking to mitigate logistical complexities, time-to-market, and supply chain risks by bringing production nearer to the end consumer. Eliminating overproduction and producing on demand, this nearshoring model drives profitability even in highly regulated and high-cost markets while contributing to local economies and removing transport-related waste.

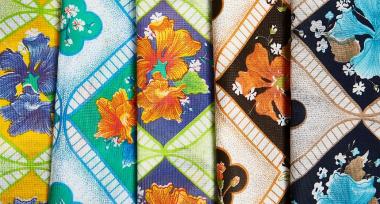

Serving as a fulfilment site and academy for training production, the Centre includes both Kornit Presto direct-to-fabric and Kornit Atlas MAX direct-to-garment systems, as well as numerous graphic design and workflow tools and systems to enable cut-and-sew operations for a comprehensive “pixel to parcel to doorstep” cycle. Consolidating the process into a single location helps maintain full visibility and control of operations and products. Taking this one step further for creators and brands, visitors can experience the KornitX Global Fulfilment Network, enabling customers to create both new sales channels and accessibility to enable production on demand. Attendees can see how Kornit’s single-step digital production technology empowers unlimited graphic expression using less floor space, resources, waste, and time—all at higher margins.

“This Innovation Centre makes it possible to capture the full, end-to-end production process in one, single location,” said Jenny Holloway, Chief Executive Officer, Fashion-Enter. “The beauty of having print on demand means there are no minimums, so we can make one garment, or we can make up to 30,000 garments a week from all locations at the same fixed cost. Here, we can also train future generations on the right way of producing garments for today, responsive to demand, with minimal waste—ethical and sustainable. This is the future of fashion and textiles.”

Kornit Digital Ltd. Fashion-Enter Ltd. Nachhaltigkeit Innovation Fashion Mode Digitalisierung EMEA

pr4u