ITMA ASIA + CITME: A success for VDMA member companies

This year’s edition of ITMA ASIA + CITME proved to be a success for the exhibiting VDMA member companies. Measured by booked square metres, Germany had the largest contingent, among the foreign exhibitors. More than 40 VDMA member companies were exhibiting their innovative products in Shanghai.

Dr. Janpeter Horn, chairman of the VDMA Textile Machinery Association noted: “Although facing a difficult market situation, this year’s edition of ITMA ASIA + CITME has exceeded the expectations, both in terms of the number of visitors and the quality of the talks. The significant number of foreign visitors to the fair was particularly pleasing.”

Solutions were demonstrated for more sustainable textile productions by most of the exhibitors, and here the VDMA members presented their technologies for saving water, energy and raw materials under the heading “Smart technologies for green textile production.”

Dr. Uwe Rondé, CEO, Saurer Intelligent Technology AG explained: “Saurer is satisfied with both the number of visitors and the quality of the discussions. Our booth was full from morning to evening with customers focused on latest technologies within the three mega trends: recycling, automation and digitalisation. Although machine utilisation in the spinning mills is still well below average, people are already gathering information and thinking about what to invest in once the market recovers.”

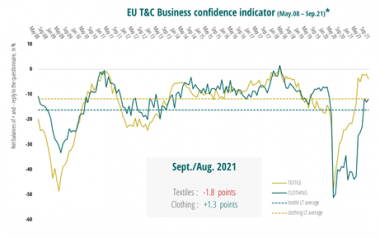

Benjamin Reiners, owner of Reiners + Fürst stated: „This year’s ITMA ASIA + CITME has exceeded our expectations by far. Especially the first day - a Sunday - has brought many high-quality customers and exclusively decision makers to our booth. We estimate about 20% international customers mainly from Bangladesh, Egypt, India, Iran, Pakistan, Uzbekistan and Vietnam. All customers agreed that the market situation at the moment is difficult, capacity usage is between 50-75% in the ring spinning sector and improvement is expected not before the 2nd half of 2024. Nevertheless the general spirit is very positive.“

“This ITMA ASIA was a great success for Trützschler. We welcomed a large number of Chinese visitors to our booth, as well as a significant number of interested international visitors”, said Dr. Bettina Temath, Head of Global Marketing Trützschler Group SE.

Georg Stausberg, CEO of the polymer processing solutions division and chief sustainability officer of the Oerlikon Group stated: „We can look back on a successful show where we were able to meet many of our customers not only from China, but also from Pakistan, India and Indonesia, for example.”

“A very well-attended trade fair, with interesting discussions, great innovative topics, in line with the modern and rapidly developing China" noted Wolfgang Schöffl, head of product line weaving machines and member of the extended management, Lindauer Dornier.

The VDMA Textile Machinery Association and VDMA China were present at the fair, to support the members e.g. with regard to IPR. With the help of a VDMA expert and a contracted law firm, the member company Sahm submitted a complaint application for patent infringement disputes during the exhibition to the onsite IPR office. Both parties, Sahm, and the Chinese company, that used patented design without permission reached an agreement: The Chinese company had to stop displaying functions and designs involving patent infringement on site which meant the removal of some structural parts and the covering of key components protected by patent protection.

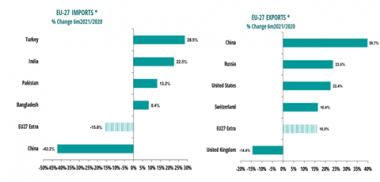

Dr. Harald Weber, managing director of VDMA Textile Machinery concluded: “Asia, and China in particular, represent the primary foreign markets for the VDMA member companies in the sector. The Chinese market is the main destination for their exports. Other major export destinations in Asia include India, Pakistan, Bangladesh and Uzbekistan. ITMA ASIA + CITME provides a unique platform to showcase technologies for customers directly in Asia. The VDMA member companies are looking forward to the coming edition of the fair from 14 to 18 October 2024 in Shanghai.”

The latest survey of VDMA members' subsidiaries in China gives reason to hope that the economic situation in the Chinese textile industry could also improve significantly in the second half of the year. In addition, European textile machinery manufacturers are urged to be present on the most important market and at the trade fair and to offer Asian customers most advanced technology for their demanding challenges.

VDMA e. V.

Textile Machinery