Commercialization of Fraunhofer´s tape-placement and tape winding systems

The two AZL Partners Conbility GmbH and Fraunhofer IPT, Aachen started their long-term cooperation for the further development and for the commercialization of Fraunhofer´s tape-placement and tape winding systems with in-situ-consolidation by the usage of laser or IR heat sources.

With this cooperation, the company Conbility GmbH makes 25 years of expertise in special machine development of tape placement systems of the Fraunhofer Institute for Production Technology IPT commercially available. Conbility offers two different tape processing systems available in different configurations.

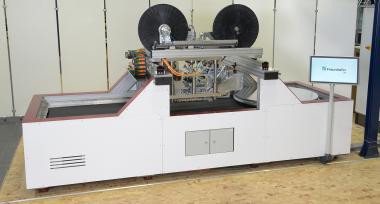

The “PrePro 2D” machine system allows for the automated tailored tape placement of UD laminates and which can be used for subsequent thermoforming or as stiffening structures in injection molding processes. The machine comprises a rotating and translational table which is moved relatively to the applicator station. The table is scalable according to the requirements of customers. Standard table diameters are 1200 mm or 2000 mm. The applicator station can be equipped with a single or with multiple spool applicators. Because of the large process area, a 9 kW IR heater is used for the in-situ-consolidation process.

Three in one: Three technologies included in one single modular system

Furthermore, the award-winning “PrePro 3D” tape placement and winding applicator is available as modular product with decentral control system (including closed-loop control of energy input into the processing zone) for the “plug-in” implementation in existing robot systems or machine systems by standard interfaces for the communication with the master control system. Conbility provides the single applicator as well as turn-key ready systems including the robot and handling systems.

Unique selling point of the PrePro 3D system is its multifunctional range of usage: it accomplishes laser-assisted thermoplastic tape placement, IR-assisted thermoset prepreg placement and dry fiber placement: Three technologies included in one single modular system.

During the JEC World in Paris (March 6th – 8th 2018), Conbility GmbH will present its new “VCSEL Tape Placement and Winding Applicator” (Fig. 3), developed in cooperation with Fraunhofer IPT and Philips Photonics at the AZL Composites in Action area (Hall 5A, C55).

VCSEL Laser Systems as heat source for lower investment and process costs

This applicator uses an integrated VCSEL Laser System as heat source which has been developed by Philips Photonics. This tape placement and winding applicator can also be integrated as modular “plug-in” system into industrial jointed-arm and linear gantry robots in variable manufacturing cells. Using the new VCSEL Laser as heat source (VCSEL: Vertical-Cavity Surface Emitting Laser) leads to significant lower investment and process cost in comparison to other laser systems. Furthermore, the VCSEL laser system can accomplish controllable in-process adjustments of the laser-spot geometry as well as the intensity distribution within the spot size during the process (in-process control of laser-spot geometries and intensities) for the first time. The new system with 2 kW laser power and 10 separate emission zones which can be controlled separately will be shown at JEC World in Paris 2018 as new product of Conbility GmbH.

“PrePro 3D“ applicator for modular integration into existing production systems. (c) Fraunhofer IPT.

“PrePro 3D“ applicator for modular integration into existing production systems. (c) Fraunhofer IPT.

VCSEL Tape Placement and Winding Applicator. (c) Conbility GmbH.

VCSEL Tape Placement and Winding Applicator. (c) Conbility GmbH.

AZL Aachen GmbH in Kooperation mit dem Aachener Zentrum für integrativen Leichtbau (AZL) der RWTH Aachen