BASF 3D Printing Solutions Presented Cutting-Edge Manufacturing Solutions at K 2019

- Comprehensive 3D printing expertise in the automotive, aerospace, consumer goods and medical application sectors

- Hands-on application presentation with a leading RV and trailer manufacturer

- Content-rich Live Talks with industry-leading business partners

- Live demonstration of pigmented plastic filaments with BASF Colors & Effects

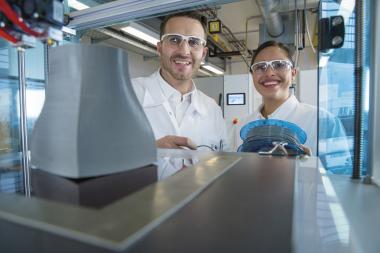

BASF 3D Printing Solutions (B3DPS) exhibited for the second time at K 2019 in Düsseldorf, Germany. At the world’s biggest trade show for plastics and rubber industry, B3DPS welcomed visitors from October 16 through 23 at the BASF SE stand C21/D21 in Hall 5 and presented its extensive portfolio of 3D printing materials and service solutions aiming at enabling industrial additive manufacturing at scale. What’s more, the company’s 3D printing experts did offer insights into the latest technological innovations and application developments in the “competencies” section.

Customized 3D printing highly attractive to RV and trailer market

The Concept Caravan at the BASF stand gave visitors hands-on experience of the impressive spectrum of applications offered by B3DPS. Alongside complex samples of printed modular construction elements, over one hundred individual parts have been 3D-printed using advanced photopolymer, filament and powder-based ready-to-print material formulations. The RV and trailer market is exceptionally attractive as it can greatly benefit from unique advantages offered by additive-based manufacturing, namely the high customizability of parts with complex geometries as well as the rapid availability of production parts without incurring tool costs. The very diverse material characteristics of the construction elements meet the production requirements for both vehicle exteriors and interior fittings. In addition, the final coating of manufactured parts plays a decisive role in many application areas, and this is also covered by the comprehensive BASF technology portfolio.

BASF 3D Printing Solutions GmbH