Texworld Apparel Sourcing Paris: Weaving the future!

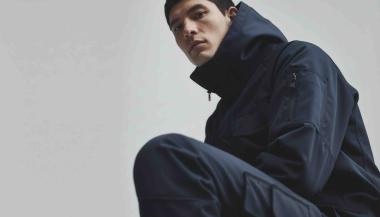

From February 2 to 4, 2026, Texworld Apparel Sourcing Paris will again bring together key players in textiles and clothing at the Paris-Le Bourget Exhibition Center. For 3 days, visitors will discover, compare and select among 1,300 suppliers who will shape the collections of tomorrow, from ready-to-wear to luxury.

Crossroads for fashion professionals

As a barometer of the international textile industry, this 58th edition of Texworld Apparel Sourcing Paris will gather over a thousand exhibitors, fabric makers and manufacturers of finished products, coming from around thirty major producing countries. This diversity confirms the lasting role of European markets in global demand and highlights Paris’s strategic position as the capital of fashion, sourcing and creativity.

The development of the Spring-Summer 2027 collections will remain at the heart of discussions with buyers, with creative directions revealed by the show’s artistic directors, Louis Gérin and Gregory Lamaud. Sustainability and supply chain traceability, central concerns for market players, will also be highlighted through dedicated itineraries, conferences and the Texpertise Econogy tools developed by Messe Frankfurt to identify innovations and industrial partners committed to more responsible production (Econogy Finder, Econogy Talks, Econogy Tour...). The Econogy HUB, located in the passage between Hall 2 and Hall 3, will focus on the sustainable initiatives and actions of the show’s partners.

A redesigned sector layout

While the overall structure of the show, centered around Halls 2, 3 and 4, remains unchanged from the past two editions, Messe Frankfurt France has decided to rethink the distribution of major sectors within the exhibition space. The goal is to meet the expectations of buyers who want to explore fabrics and finished products in one continuous flow while optimizing their visit. The Apparel Sourcing area dedicated to women’s wardrobes (All about her) and Texworld’s Knit offer will move to Hall 3, alongside the national pavilions. In Hall 4, Texworld’s Activewear sector will be grouped with the Casual & sport clothing area, while Print and Jacquard will be placed closer to Silky Aspects, strengthening the women’s ready-to-wear offer. Hall 2 will remain dedicated to trend forums, round tables and services areas (food, networking...) while also offering comfortable breathing zones.

This new organization makes it easier to connect different product worlds according to their uses and types, strengthening synergies between Texworld and Apparel Sourcing exhibitors. Buyers can now move naturally from one skill to another and circulate freely between materials, accessories and finished product lines, enjoying a smoother sourcing experience with easier navigation.

Areas dedicated to showcasing products and expertise

Visitors will find several features that were highly appreciated in previous editions. Initiatives, the showcase area dedicated to craftsmanship and collective projects from industries or countries, will be accessible at the entrance of the show. As an area that highlights textile identities and the know-how of French and European training schools, it will offer an expanded view of international expertise. The Ready to Sell area, located in Hall 2 near the trend forums, will present a carefully curated selection of finished products chosen by Texworld’s artistic directors. Buyers will be able to quickly identify collection suggestions available from exhibitors, in line with the creative trends shaping the coming season. These features help make Texworld Apparel Sourcing Paris both a practical and forward-looking service platform.

Texworld Apparel Sourcing Paris Paris-Le Bourget Exhibition Center hall design ready-to-wear luxury fashion Spring Summer 27

Messe Frankfurt France