Digitak services always in fashion with Mimaki sublimation and direct printing

- Specialised in dye-sublimation printing, the Italian company has conquered the heights of the high fashion sector with its top-quality printed fabrics.

- With its recent investment in a direct-to-fabric printing line, Digitak is preparing to expand its range of printed products, focusing on fabric differentiation.

Dye sublimation printing of high fashion designs is the beating heart of Digitak, an Italian company specialised in digital textile printing. Operating in the textile district of Lombardy, Italy, the company has established itself among the main suppliers in the world of high fashion and sportswear in just under 15 years.

Making production versatility one of the cornerstones of its philosophy, Digitak has continued to invest in technology, as well as research and development its product portfolio. This forward-thinking approach has enabled the company to guarantee innovative, personalised products with meticulous attention to detail, with the highest – almost obsessive – standards of quality and maximum design flexibility. Over the years, the extensive experience gained by the company’s management in the field of sublimation with traditional and digital techniques, combined with their investment decisions have allowed Digitak to enhance its production performance, gradually implementing higher quality standards and differentiating itself from the competition in the complex and competitive sector of high fashion. An important feat, which has not, however, dampened its enthusiasm and willingness to continue growing and exceeding its goals. The company’s latest investment in a direct-to-fabric digital printing line with pigment ink propels the company into a new and promising production dimension.

Sublimation printing specialists

Since Digitak’s establishment, Filippo Taccani, the founder and current owner of the company, had set himself a clear and ambitious objective: “I wanted to take up the challenge of operating digitally - printing fabrics using this innovative technology to create products on a par with those I had achieved with traditional sublimation textile printing methods during my previous work experience.”

The purchase of a Mimaki JV4 plotter, one of the first to be installed in Italy, marked the beginning of Digitak’s adventure. “To start the business, I needed a printing system that could operate with dispersed inks to print on polyester and I found the JV4 to be the best option,” explains Taccani. “It was an excellent decision, because I used these plotters to build the company and its success.”

The first Mimaki plotter was in fact followed by a second and a third. When it bought the fifth, the company moved to an industrial unit in Tradate (Varese) – Digitak’s current site – which now houses around fifteen Mimaki JV33 plotters, in addition to three Mimaki TS500-1800 wide-format sublimation printers, and a Mimaki TS300P-1800 high-speed sublimation printer. This Mimaki powered production facility – which is one of the company’s core strengths – was recently expanded with the addition of a Mimaki TX300P-1800B belt-type hybrid printing system, together with a Mimaki TR300-1850C textile coater and a Mimaki Tiger-1800.

“Naturally, over the years, we have also tested printing systems from other suppliers, but we have always returned to Mimaki. With high fashion as our key market, we need to guarantee our customers the highest levels of quality and, to date, we have never found solutions that beat the quality of this Japanese brand’s technology.”

According to Taccani, the difference lies in the “calligraphy” of Mimaki’s machines, that is the line of the ink on the fabric: “Unlike its competitors, Mimaki has focused on the ‘waveforms’, i.e. the electronics associated with the print heads. This attention paid to the way the ink jet is managed from the print head has allowed Mimaki to achieve unparalleled levels of accuracy, an aspect that has given my company a clear competitive edge.”

Moreover, at Digitak, quality comes before quantity: “We prefer to dedicate an extra day to production to guarantee the customer a final product that fully meets requirements and expectations. Mimaki’s technology not only suits this business model bult on top quality, but it crucially enables it.”

Operational and creative flexibility

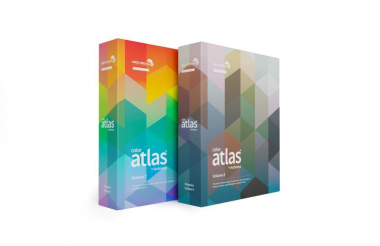

Digitak currently prints around 2,000 linear metres of fabric per day. Its portfolio ranges from clothing and scarves, to beach and swimwear, with related personalised accessories, to sportswear, with technical properties such as breathability, comfort, resistance to external agents. The company have even added customised outdoor furniture to their offering of diverse and creative products.

The company’s machines operate continuously, 24/7. During the day, the machines are mainly used to develop and produce samples and colour proofs, while the actual production is carried out at night. “Thanks to our technology, we have developed an extraordinary operational flexibility. The fact that we have so many plotters allows us to work on multiple designs at the same time and to launch projects that are also very different from one another,” explains Taccani. “There are also some other crucial factors that have contributed, and continue to contribute, to increasing our production efficiency. The reliability of Mimaki’s solutions and the remote monitoring option offered is key. Once the standard start-up monitoring has been carried out and the machines are found to be printing correctly, we can let them work overnight without an operator. This is a great benefit for people who, like us, manage such a large and diverse fleet of machines.”

Digitak takes the same approach to customer service. Faced with an increasingly demanding market in terms of creativity, precision and completeness of service, the company wants to guarantee flexibility and customisation. “We decided to set up a department dedicated to the pre-press stage, in charge of preparing and checking the files supplied by customers. Seldom do our teams not need to do some editing of the files supplied, even if it’s only to make small changes that are essential for the print document to be as suitable as possible and to achieve the best final result.”

Technologies of the future

With a view to further enhancing production and customer service, Taccani has chosen to take on a new challenge, switching things up with some of the most recent investments.

While maintaining the focus on dye sublimation printing, Taccani has focused on technological diversification by installing a direct-to-fabric digital printing line. This consists of a Mimaki TX300P-1800B printing system with pigment inks and a TR300-1850C coater from Mimaki’s TR series. “The market continues to evolve and now requires even more flexibility regarding both processes and the fabrics supplied. This means that great opportunities exist for a print shop capable of simultaneously producing the same design – with minimal colour adjustment – on different fabrics, guaranteeing similar and accurate results. And this is precisely the path we are taking,” says Taccani. “Why have we opted for Mimaki again? Well, I had an opportunity to try out their new pigment inks and I immediately realised that they are a generation ahead of the other pigments available on the market. The cyan is very clean, the black is deep and there is a very interesting fullness of colour, suitable not only for furnishings, but also for other applications in the clothing sector.”

With its pigment inks, the new direct-to-fabric printing line allows Digitak to explore other related market segments. Thanks to the innovative automatic belt system, the TX300P-1800B guarantees good productivity and high-quality results. A standard of quality that is also boosted by the TR300-1850C fabric pre-treatment system: “This coater is essential for ensuring the best possible preparation of fabrics for printing. In fact, we are able to treat fabrics to make them suitable for the type of print they are intended for, sanitise them for specific applications and, in some cases, even dye them, with excellent quality.”

According to Taccani, another beneficial factor of direct-to-fabric pigment printing technology is the eco-sustainability of the process and its lower environmental impact. “We are proud to be able to offer our customers excellent printing results using little water and printing in ‘green mode’, with both the technologies we have available. I consider them winning technologies for the future, as both dye sublimation printing and direct-to-fabric printing with pigment inks use little water while mainly requiring the use of energy. Therefore, if you use renewable energy, then you’re done.”

Digitak’s other trump card is the Tiger-1800 installed in 2019. With this industrial printing system, the company aims to increase production volumes while maintaining its high-quality standards and further optimising costs. “We are excited to have these promising technologies available to us in-house. We are currently experimenting with these solutions, testing new opportunities and evaluating which paths to take to stay ahead of the game,” concludes Taccani.

Mimaki Europe B.V.