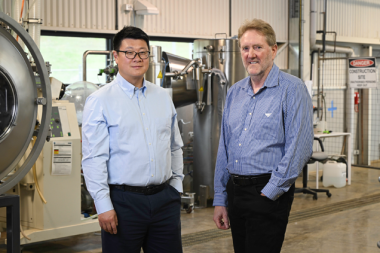

CHT USA celebrates expansion of its headquarters in Michigan

With a ribbon cutting ceremony on October 24, 2023 CHT USA celebrated the $ 25 million expansion at its US headquarters in Cassopolis, Michigan. More than 100 attendees came to the celebrations, among others officials from local, county and state governments, neighbors, and area business leaders, CHT employees, CTO Dr. Bernhard Hettich as representative of CHT’s Global management team, and members of the press.

In his speech, Dr. Bernhard Hettich, CTO of CHT Group, thanked the local authorities for their business-friendly policies and stated that a development towards sustainability in many areas would not be possible without CHT's silicone products: "With CHT's largest single investment outside Europe, CHT is taking a big step and doubling its silicone production capacity. We intend to use this expansion not only to support our customers in the Americas, but also to leverage the capacity for our global growth. In line with the motto "CHT first", further steps in this direction will follow."

For the Cass County site, the approximately 45,000 square feet new facility with 5 reactors and distillation units resulted in an increase in the total area of the company's site to 120,000 square feet. This will then allow sufficient space for additional reactors and downstream processes. The CHT USA site expansion has created approximately 30 highly skilled jobs in the community.

CHT USA’s Regional Sales and Marketing Director NORAM, Matthew Loman hosted the Ribbon Cutting ceremony.