Oerlikon celebrates four world premieres at ITMA Barcelona 2019

- Clean Technology. Smart Factory.

Remscheid – Oerlikon invites all visitors to this year's ITMA in Barcelona on a journey into the future of manmade fiber production. From 20 to 26 June 2019, the world market leader will show all its guests its vision of a sustainable and automated manmade fiber production in a virtual 4D showroom at its 1,000 m² stand in Hall 7, A101: "Clean Technology. Smart Factory." is the motto of the future. And this is only a stone's throw away from reality at the stand. Because today Oerlikon is presenting four world premieres for efficient machine and plant concepts in a new, innovative industrial design. Together with numerous other innovations, all this forms the new DNA of the Oerlikon Manmade Fibers segment.

The challenges for the manmade fiber industry are manifold and Oerlikon shows its customers solutions:

1. Choosing the right business model

Price pressure on fiber and yarn manufacturers is growing due to global market consolidation. Here it is important to position oneself correctly. Are you producing polyester, nylon or polypropylene for the niche market and skimming off good margins with innovative products and ingenious material properties, or are you looking for business success through economies of scale in the volume market such as the constantly growing apparel sector? Oerlikon has the right answers for both business models. And the most important thing: the market leader supplies all solutions from a single source. See for yourself at the world premieres of the machine and system concepts of WINGS FDY PA6, BCF S8 Tricolor and the revolutionary eAFK Evo texturing machine.

2. Finding alternatives for good personnel

Finding good operators in the manmade fiber industry is becoming increasingly difficult, even in emerging industrial nations such as China, India and Turkey. The solution is obvious. What, for example, the automotive industry achieved years ago with the 3rd Industrial Revolution is now also taking its course in the textile industry. And at the same time it is even shifting up a gear. In the next step, automation in combination with digitization will lead to new, sustainable production. Oerlikon will be showing how automation and digitization interact at ITMA. Self-learning machines and systems, artificial intelligence (AI), remote services and edge computing are just a few of the key words in the digital half of the new Oerlikon Manmade Fibers DNA.

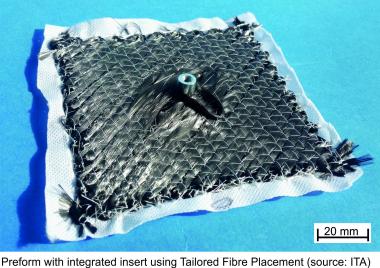

3. Guarantee quality and traceability

The qualities of the fibers and yarns must meet the highest demands and their production must be traceable throughout the textile value chain. This no longer only plays an important role in the automotive industry, where safety is of paramount importance. Other branches of industry that use fibers, yarns and nonwovens also want to know where the raw materials they produce for consumer articles come from. Legal regulations are demanding this more and more frequently. Oerlikon offers optimal solutions with its DIN ISO certified manufacturing processes. More than half of the world's manmade fiber producers are convinced every day that the qualities produced on Oerlikon Barmag, Oerlikon Neumag and Oerlikon Nonwoven equipment are right – and all visitors to ITMA can do the same on site.

4. Efficient and sustainable production

In the future, the materials produced from manmade fibers must become part of a further improved global recycling economy. The recycling of polyester – with over 80% market share the most frequently used manmade fiber in the world – has not only been on the agenda since today. Oerlikon already has solutions at hand: from PET bottles to fibers and filaments, to textiles and carpets. ITMA is the next step. With the VacuFil® Oerlikon in cooperation with the subsidiary company BBEngineering presents the world premiere No. 4 – a recycling solution within a running polyester production with a waste-free approach.

Vision becomes reality

The Oerlikon Manmade Fibers segment thus demonstrates what the ITMA in Barcelona promises as the world's leading trade fair for textile machinery and plant construction: "Innovating the world of textiles – sourcing for a sustainable future". In Hall 7, A101, this is already reality.

Oerlikon