Carbios: White PET fiber from colored textile waste

- Carbios has succeeded in producing a 100% enzymatically recycled white PET fiber from colored textile waste

- At the same time, the company has produced the first 100% recycled PET bottles, that have successfully passed the food contact validation tests, from the same textile waste.

- Carbios received €827,200 for the validation of this final technical stage of the project co-funded by ADEME

Carbios announced the validation of the 3rd and final technical step of the CE-PET research project, co-funded by ADEME3 (France’s Environment and Energy Management Agency), for which Carbios is the lead partner alongside its academic partner TWB. This achievement confirms, once again, the full potential and breadth of Carbios’ enzymatic recycling process, C-ZYME™. This breakthrough innovation makes it possible to produce a wide variety of products of equivalent quality to those of petro-sourced origin from any PET waste, including textiles.

The first white PET fiber recycled enzymatically from colored textile waste

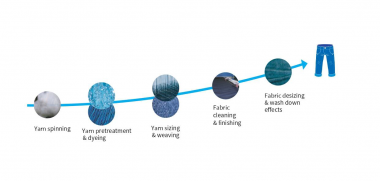

Worldwide, around 90 million tons of PET are produced each year, more than 2/3 of which are used to manufacture fibers. However, only 13% of textile waste is currently recycled, mainly for downcycling, i.e. for lower quality applications (such as padding, insulators or rags). By successfully manufacturing at pilot scale a white PET fiber that is 100% enzymatically recycled from colored textile waste, Carbios is paving the way for the circular economy in the textile industry. C-ZYME™ is now on the doorstep of industrialization and will soon enable the biggest brands to move closer to their sustainability goals.

Emmanuel Ladent, Chief Executive Officer of Carbios: « Thanks to our breakthrough process, it will soon be possible to manufacture, on a large scale, t-shirts or bottles using polyester textile waste as raw material. This is a major breakthrough that gives value to waste that currently has little or no value. It is a concrete solution that opens up a global market of 60 million tons per year of potential raw materials and will help to reduce the use of fossil resources. »

Separate collection of textile waste soon to be mandatory in Europe

From 1 January 2025 the separate collection of textile waste, which is already in place in some countries, will be mandatory for all EU Member States (European Directive 2018/851 on waste). Carbios’ process will enable this waste to be sustainably recovered and included in a true circular economy model.

These technological validations were carried out as part of the CE-PET research project, co-funded by ADEME3. In particular, the project aimed to develop Carbios’ enzymatic PET recycling process on textile waste. The C-ZYME™ technology is complementary to thermomechanical recycling and will make it possible to process plastic and textile waste deposits that are currently not or poorly recovered. For the validation of this stage of the project, Carbios received €827,200 (€206,800 in grants and €620,400 in repayable advances).

Carbios