C.L.A.S.S invited to present ‘smart innovationeducation’ space at Copenhagen Fashion Summit 2019

C.L.A.S.S ‘takes action’ and shares the very smartest textile and material innovations available globally today as part of a carefully curated space to be unveiled at the 10th anniversary of the Copenhagen Fashion Summit. This two-day event will take place from the 15th - 16th May at The Copenhagen Concert Hall.

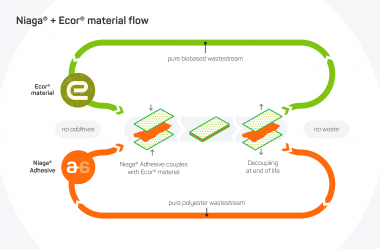

With education right at the heart of this unique presentation, C.L.A.S.S will share valuable insights and physical examples of some of the most sustainably responsible innovations available on the market today, empowering the next generation of designers as well as those from leading design houses, with the chance to experience first-hand how they might work towards a circular design economy.

Located within the Design Studio area, key members of the C.L.A.S.S ACTIVATE team will be on hand to share valuable insights gleaned from over 12 years of research and development within this area helping to provide visitors including new designers, start-up’s, and established designers with everything needed to make ‘smart’ choices that work vertically through the supply chain from merchandising right through to consumer facing communication campaigns. From trends, new R&D concepts, and the latest buzzwords, C.L.A.S.S has it covered.

C.L.A.S.S.