Kornit Digital presents Enhanced Presto MAX at ITMA

Kornit Digital LTD., a leader in sustainable, on-demand digital fashionx and textile production technologies, announced the Company is taking the power of digital fashion to new heights with enhancements to the Kornit Presto MAX system for digital fabric decoration on demand.

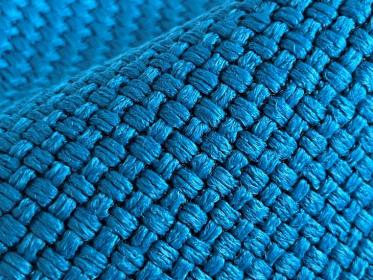

Designed with the fashion and home décor industry in mind, the enhanced solution presents innovative capabilities for transforming virtual concepts into custom fabrics, supplementing digital efficiency and quality with white printing on colored fabrics. The new NeoPigmentTM Vivido ink achieves darker, deeper blacks and colors and establish new fashion standards with a pigment-based process. Kornit’s patented solution offers a streamlined and completely dry process for the a sustainable fabric decoration.

At ITMA 2023, Kornit will also be displaying an end-to-end partner ecosystem – underscoring how integrated solutions ensure a smooth transition towards a digital infrastructure and enable long-term business growth. Highlighting the power of partnership alongside Kornit is Greentex.co, a supplier of textiles and apparel leveraging digitally enabled, eco-friendly waterless printing. The company will be showing Presto MAX with fabrics highlighting the depth of black inks. Working alongside Kornit, Zünd will demonstrate how its modular cutting systems is the foundation for an end-to-end “eco factory,” completing fashion decorated by Presto MAX with their digital cutting solutions. Pentek Textile Machinery joins to display the possibilities for inline, sustainable softening of fabrics for unique and demanding applications.

Kornit Digital